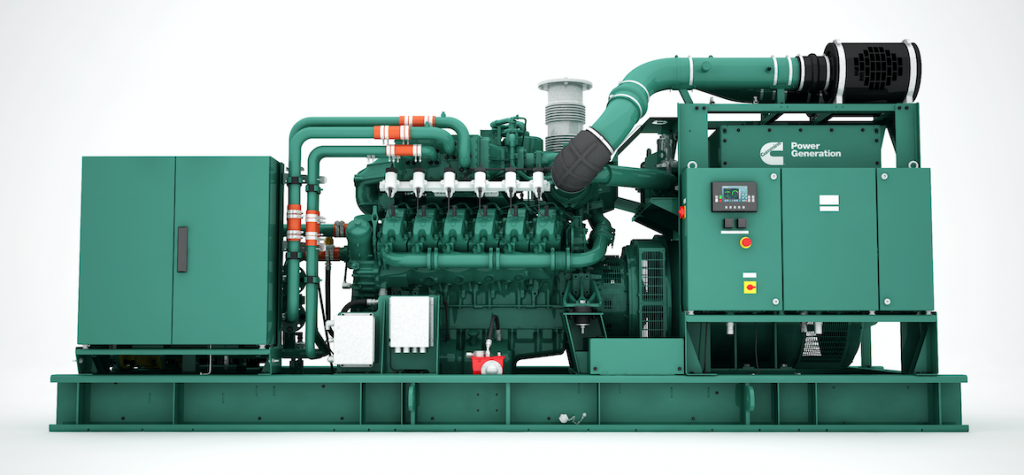

Cummins C25G: so close and so far

Cummins C25G: just presented is already a must both near, very close to Ramsgate, home of the preview, and far away, in the Far East. Let’s read the officials. Cummins Inc. announced the successful long-term field test of its latest natural gas-powered generator, the C25G, which has been operational at the Cummins Power Systems Manston […]

Cummins C25G: just presented is already a must both near, very close to Ramsgate, home of the preview, and far away, in the Far East. Let’s read the officials.

Cummins Inc. announced the successful long-term field test of its latest natural gas-powered generator, the C25G, which has been operational at the Cummins Power Systems Manston site in Kent, England, since September 2019.

Cummins C25G has been sighted in Kent

Launched at Middle East Energy in March 2020, the C25G gas generator series is the latest addition to the Cummins natural gas generator portfolio. To test the generator to its limit in a real-world setting, Cummins installed a C25G inside a test cell at its Power Systems Manston engineering and logistics facility and took the 10,000 sq. mt. site ‘off-grid’. The generator ran for 60 days – 24 hours a day from Monday to Friday and for 12 hours a day Saturday to Sunday – fuelled by pipeline natural gas meeting Cummins Power Systems Manston facility’s electricity requirements.

Tejaskumar Amin, Global Chief Engineer for Cummins Power Systems, said: «We have a strict testing regime for our new products, however, we wanted to push the C25G to its limit in a real-world setting; and as the generator is ideal for factories, we decided to use it to power our own site. Such a field-test is unique in Cummins’ 100-year history and we learned a lot about the product which will enable us to serve our customers better. The test is yet another example of how Cummins is working hard in reducing its carbon footprint through not only producing its own power but also exporting the surplus power to the grid. This underlines Cummins’ commitment to its own Planet 2050 Strategy, which includes reducing absolute greenhouse gas emissions from Cummins facilities and operations by 50%, as well as cutting absolute lifetime global greenhouse gas emissions from newly sold products by 25%.»

Over the course of the test, the C25G supplied a daily average of 300kWh of electricity to the site and exported around 200kWh of electricity to the national grid. With such an installation, Cummins gained huge financial savings and reduced the electricity consumption and reliance from the grid. The C25G is engineered to deliver superior fuel efficiency with a power density of 500kW (50Hz) and 580kW (60Hz) from a 25L engine, while providing reduced maintenance costs per kWh. The C25G generator series offers a total package of gas generator capabilities for prime, peaking power and island mode applications, while being suitable for a diverse set of industries ranging from hospitals and manufacturing, to commercial building and greenhouses requiring reliable continuous operation. The C25G models comply with all global emissions regulations while delivering a high electrical efficiency of up to 41.6% (50Hz) and 40.6% (60Hz) on pipeline natural gas, down to 71 and 68 methane number (MN) respectively at full power. In addition to its generator capabilities, the advanced control systems fitted to the C25G series provide users with access to advanced monitoring, diagnostics and live trending analytics, maximizing the generators’ uptime and reducing maintenance labor costs.

Gas works also in China

Cummins has announced it has secured its first project win for its new gas-powered C25G generator series and is set to provide an office block in Shandong Province, China, with significant environmental benefits. The project team designing the 26,730 sq. metre, 18 floor commercial building, currently under construction, was looking to invest into a more efficient energy distribution system that would cover all power and heat requirements of its premises. Cummins’ C25G generator, fuelled by pipeline natural gas, was selected to offer a combined cooling, heat and power solution (CCHP). Once operational, the C25G generator will allow the building to significantly reduce energy costs, and consequent emissions, through thermal recover and overall electrical, cooling and heating efficiency. This fully integrated solution from Cummins offers 500kW of continuous power, as well as the provision of balance of plant (BOP) items such as the radiator, sound-proof enclosure, switchgear and digital master controller. Coupled with the above capabilities, Cummins Power Generation was selected to support the project due to the C25G generator’s high electrical efficiency of up to 41.6% (50Hz), low maintenance costs and better lead times. In addition to its generator capabilities, the advanced control systems fitted to the C25G series provide users with access to advanced monitoring, diagnostics and predictive analytics maximising the generators’ uptime and reducing maintenance labour costs.

Haoming Liu, Senior Gas Business Manager, Cummins Power Generation, said: «We are delighted to announce that we have secured our first project win for our C25G genset. This machine is the latest genset in our gas-powered portfolio and we look forward to seeing it providing our customer in China with a reliable power solution that not only reduces energy usage and costs, but also emissions.»

The C25G gas generator series, which has a power density of 500kW (50Hz) and 580kW (60Hz) from a 25L engine, is the latest gas generator model launched by Cummins Power Generation, joining Cummins’ QSK60G and HSK78G gas product portfolio. It offers a total package of gas generator capabilities for prime, peaking power and island mode applications, while being suitable for a diverse set of industries ranging from hospitals and manufacturing to commercial building and greenhouses requiring reliable continuous operation.