FPT Industrial at PowerGen 2023

FPT Industrial returns in its dual role of diamond premier sponsor and exhibitor at PowerGen International in Orlando (Florida, USA), the largest networking and business event for electrical generators and solutions providers engaged in power generation.

FPT Industrial returns in its dual role of diamond premier sponsor and exhibitor at PowerGen International in Orlando (Florida, USA), the largest networking and business event for electrical generators and solutions providers engaged in power generation.

From February 21 to 23, FPT Industrial will be displaying an even more complete range 3-to-13-liter engines for Power Generation applications meeting various international emission standards – Tier 3 through Stage V – offering high performance along with flexibility, reliability, and the lowest cost of ownership, with compact engine layouts. In extreme weather events, FPT Industrial guarantees a reliable and efficient source of power. The engines on display will include the F34 40kW Tier 4 Final, F34 75kW Tier 4 Final, F36 Tier 4 Final/Stage V, NEF45 Mechanical G-Drive Tier 3, NEF67 Stage V/Tier 4 Final and C9 Stage V. A dedicated customer service area, featuring the MyFPT app for real time engine diagnostics, will complete the stand.

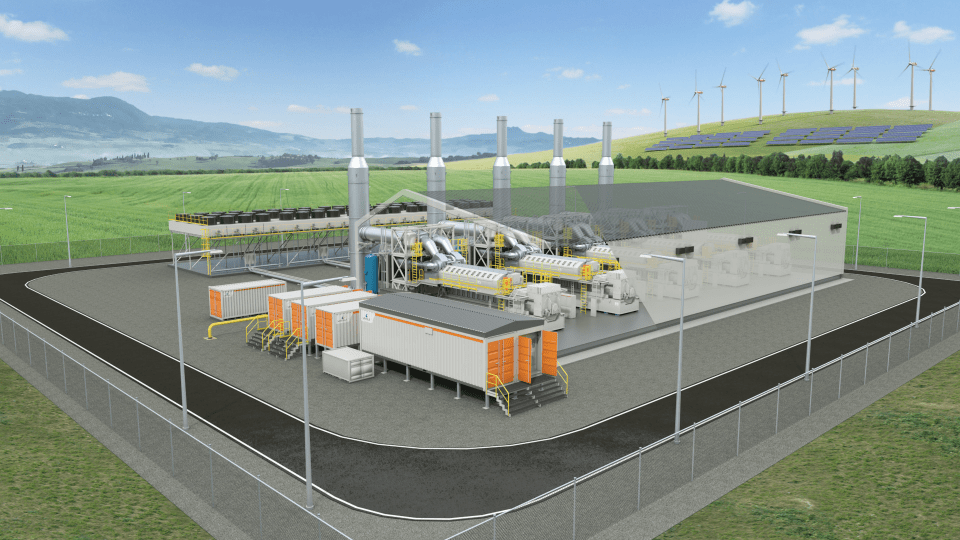

It will also feature a scale model of FPT Industrial’s ePowertrain Plant – the Iveco Group’s first carbon-neutral plant, which was inaugurated on October 18th in Turin (Italy) – which is fully dedicated to the production of electric axles for both light and heavy commercial vehicles, and electric central drives, and to the assembly of battery packs. The new ePowertrain Plant represents the embodiment of a consolidated brand strategy which aims to fully offset the environmental impact not only of its products but also of all its industrial activities.

FPT Industrial at PowerGen: shared standards of excellence

FPT Industrial is faithful to its mission to meet all customer power generation requirements in all applications, conditions and situations. That’s why it offers wide line-ups that are compliant with different emissions levels. FPT Industrial’s Tier 4 Final engines feature cutting-edge ATS technology with no DPF, providing a 95%+ NOx suppression capacity and best-in-class emissions efficiency.

The FPT Industrial Tier 3 engines on show offer dependable emergency and stationary power systems with low fuel consumption, low maintenance costs, and optimization of space thanks to their compact footprint.

Patented technologies for ultimate efficiency

FPT Industrial’s patented, DPF-free HI-eSCR technology for Tier 4 Final compliance meets the requirements of the most challenging applications, maximizes uptime, and greatly reduces operating costs. The aftertreatment components for Tier4 Final/Stage V (HI-eSCR2, which is the evolution of the HI-eSCR, compliant with more stringent emission limits) are packaged in a compact and fully enclosed structure, offering flexible layout options, and simplifying installation.The patented electronically controlled exhaust flap maximizes performance at low temperatures and low loads. Improved exhaust gas temperature control speeds up SCR light-off in the cold part of the emission cycle via an electronically controlled exhaust flap. This technology has proven to be very effective in the rental world where low load and low temperature are common conditions.

All of FPT Industrial’s Tier 4 Final and Stage V engines are fully compatible with diesel and paraffinic/renewable fuels, such as HVOs.In combination with FPT’s patented ATS technology, customers get the perfect low-emission, sustainable solution, reducing CO2 impact by up to 90%.