Gas and diesel generator sets for meat production in Mexico

Rolls-Royce supplied MTU Onsite Energy generator sets for the power plant of a new pork processing facility in Mexico, operated by one of the country’s largest and most technically advanced producers. The power plant is supported by four MTU Onsite Energy Series 4000 gas generators and one MTU Onsite Energy diesel generator under one overall […]

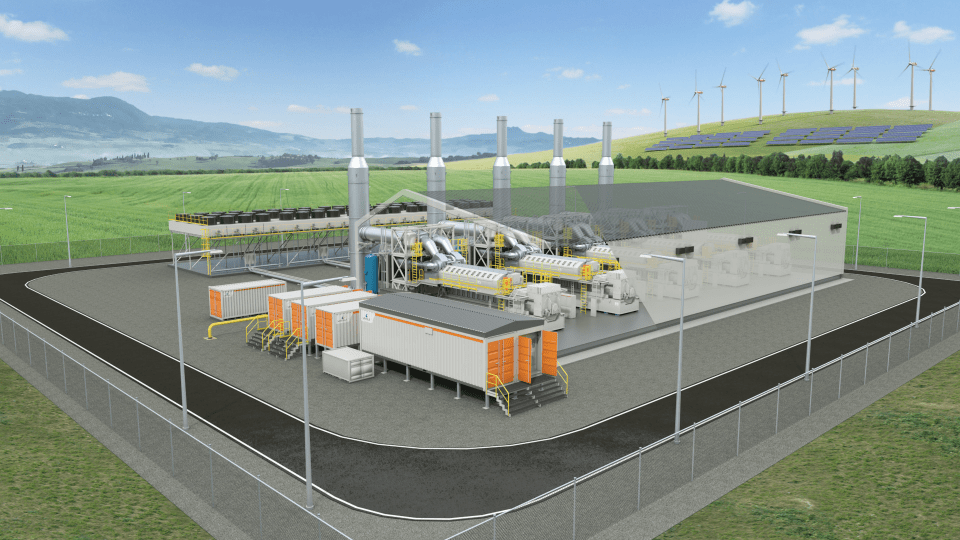

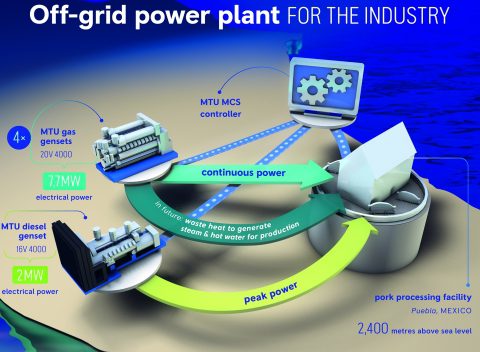

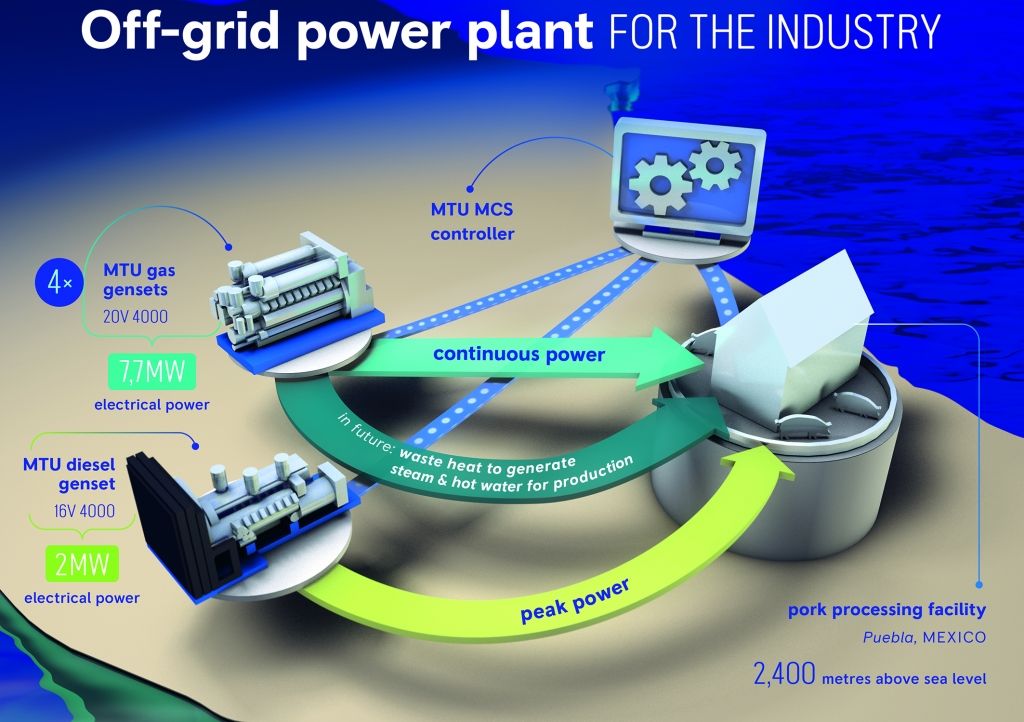

Rolls-Royce supplied MTU Onsite Energy generator sets for the power plant of a new pork processing facility in Mexico, operated by one of the country’s largest and most technically advanced producers. The power plant is supported by four MTU Onsite Energy Series 4000 gas generators and one MTU Onsite Energy diesel generator under one overall control system. The site is not connected to the grid; therefore, the power solution is completely independent. This is the first off-grid solution of its kind in the Americas for MTU.

Alfredo Carrasco, Latin American senior sales manager of MTU Onsite Energy gas power systems, said: «As the customer has to rely 100 percent on his own grid, the challenge was to deliver a complete solution which ensures grid stability on a high level. Therefore, the reliability and efficiency of the MTU Onsite Energy systems were major factors in the decision of the customer. The ability of the team to meet the customer’s stringent requirements of gas, diesel and an integrated control system from a single supplier also contributed to us being awarded this project».

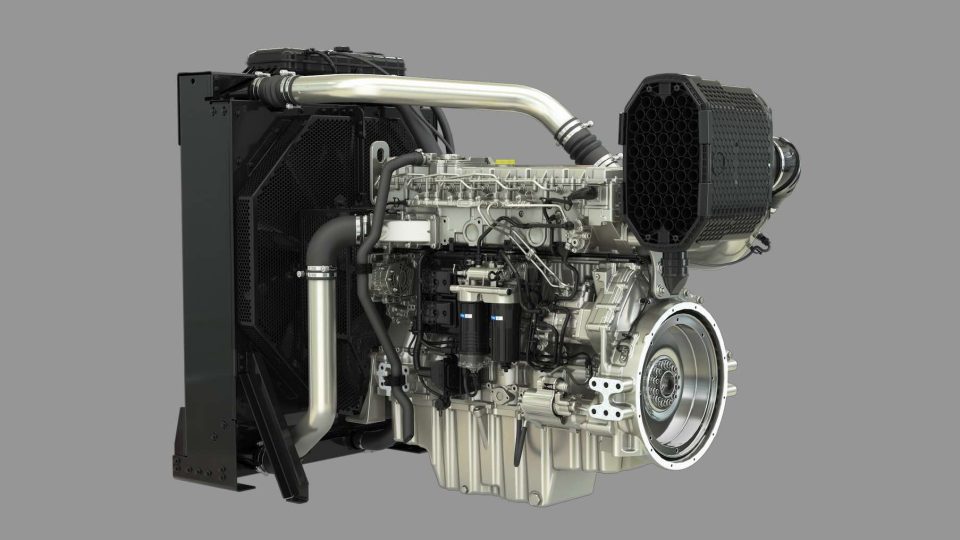

A single 16-cylinder Series 4000 diesel generator sets

The four gas units are the highly-rated 20-cylinder Series 4000 natural gas systems delivering all together 7.7 MW electrical power, capable of handling the pork processing facility’s altitude of 8,000 feet above sea level with the lowest derating, ensuring maximum power availability at the site. In a second phase, it is planned to use the heat out of the exhaust gas, the oil cooler and the mixture cooler to produce steam and hot water which can be used in the production processes.

ROLLS ROYCE EXPANSION IN THE MICROGRID MARKET

A single 16-cylinder Series 4000 diesel generator system with an electrical output of 2 MW is tasked with absorbing greater load blocks than the natural gas units, offering long-term stability to the power plant. The diesel unit will run continuously with loads as low as 10 percent to minimize fuel consumption, allowing the natural gas units to produce more energy.

MTU Onsite Energy’s MCS master control panel integrates plant control and remote operation, and all systems run in isolation from the power grid, providing reliable, stable and efficient electrical power to the entire facility.

MTU’S POWER GENERATION SYMPOSIUM

Three different fuel sources

The pork processing facility, located in Puebla, Mexico, features a power plant that will operate using three different fuel sources, including biogas from livestock waste in a later stage. With the help of the flexible MTU Onsite Energy systems, the plant will have the ability to double its power capacity in the future. The customer already owns and operates a combined heat and power (CHP) plant at a nearby facility using a medium-speed gas generator unit from Rolls-Royce.