Himoinsa supplies 8.5 MW of power to a production plant in Sierra Leone

In addition to supplying the flour factory, Himoinsa’s project challenges include the ability to feed surplus power into the local electricity grid, which will help stabilise the power supply in the Freetown area (Sierra Leone).

Himoinsa has developed a project to supply power to a production plant in the Port of Freetown, Sierra Leone, in the West African region, an area of great strategic importance due to its commercial logistics. As the port is a key component in the distribution of flour and other products throughout its area of influence, an uninterrupted power supply is essential for the continuous operation of the production plant.

The project is focused on the flour production sector, where a continuous supply of power is required to run the plant. In addition, the surplus power produced by the generator sets will be fed into the port’s electricity grid to help stabilise the supply.

The customer requires a power solution thar can meet the demand for 8.5 MW of power to supply the flour production plant. In addition, the ability to transfer surplus power to the local electricity grid is required to help stabilise the power supply in the Freetown port area, which has historically experienced frequent power outages. In this way, the customer’s expectations were to secure the power supply to the factory, minimising outages in the local grid and maximising revenue by feeding the surplus back into the grid.

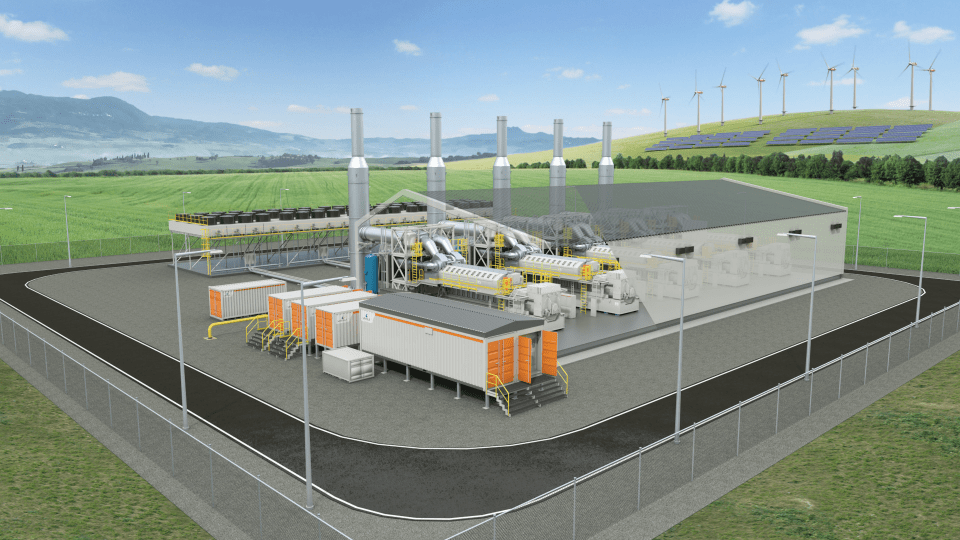

The port of Freetown has very specific space constraints, which posed a challenge for the installation of the equipment. In order to guarantee the required fuel autonomy without compromising the available space, special tanks had to be designed for the project. In this regard, Himoinsa’s teams worked in coordination with local teams and operators.

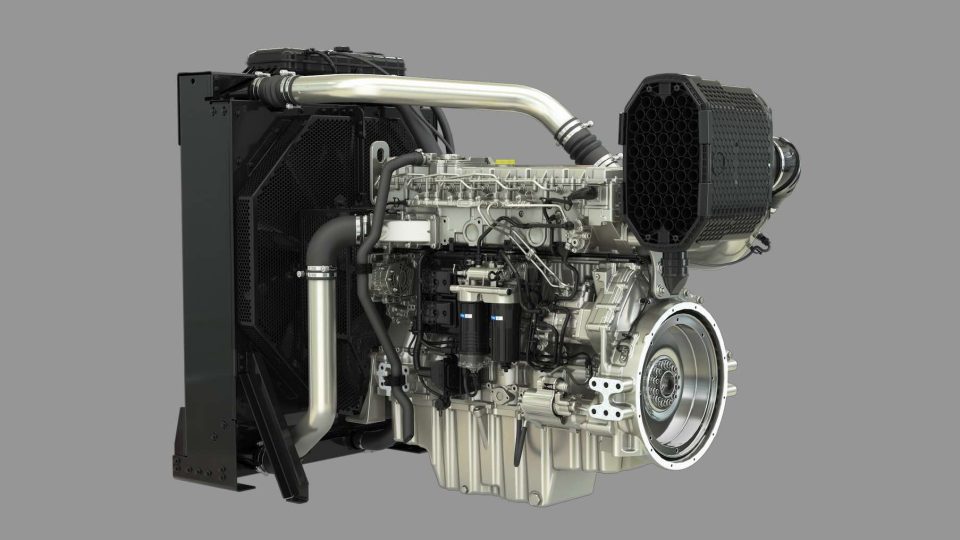

Himoinsa has designed and installed an 8.5 MW power plant consisting of a series of high-efficiency diesel generator sets designed to power both the production plant and the grid simultaneously. The solution includes: HTW-1260 T5 generator sets with advanced synchronisation technology to ensure stable power distribution; soundproofed generators installed in 20-foot containers with volcanic wool insulation to reduce sound emissions, ensuring quiet operation in a seaside environment; optimised configuration to operate at high temperatures and with different fuel types, adapting to local conditions.

The project has been carried out in a marine environment with a high salt concentration, so it was essential to ensure that the generator sets and equipment were sufficiently resistant to corrosion and the extreme conditions of the region’s tropical climate. To achieve this, special protection systems have been incorporated to ensure optimal operation of the equipment despite its proximity to the sea.

Read also: Himoinsa supplies 17 MW of emergency power for airport in Turkey