Himoinsa: S5 range with Stage V engine

Himoinsa worked closely with Stage V manufacturers for the S5 range Himoinsa has designed S5 generator sets with Yanmar, Fpt Industrial and Scania engines that include a new after-treatment system to guarantee an emissions reduction that is in compliance with EU Regulation 2016/1628 for non-road mobile machinery. This ensures a reduction of up to 90% […]

Himoinsa worked closely with Stage V manufacturers for the S5 range

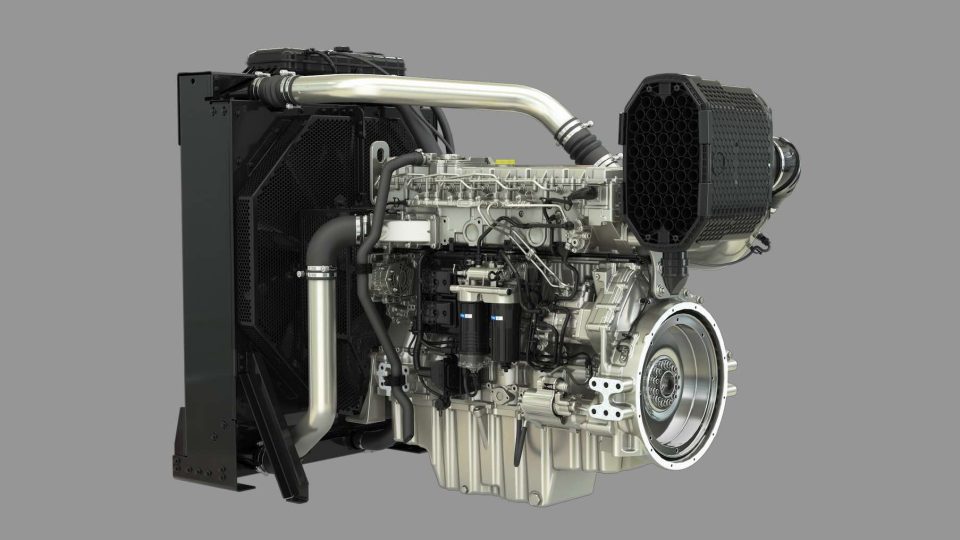

Himoinsa has designed S5 generator sets with Yanmar, Fpt Industrial and Scania engines that include a new after-treatment system to guarantee an emissions reduction that is in compliance with EU Regulation 2016/1628 for non-road mobile machinery. This ensures a reduction of up to 90% of emissions of harmful components with respect to the previous technology.

Guaranteeing a wide power range from 9 to 550 KVA, the S5 range takes into account in particular such factors as maintenance, durability, fuel consumption, and the final cost of the machine to keep it competitive in the rental sector in Europe. One of the main components of the S5 generator sets is their control units, for a secure and efficient coordination with the control units of the Stage V engines.

Main characteristics

These are compact generator sets that integrate all emission reduction systems and AdBlue’s tank in a robust and functional canopy. The new range incorporates a heavy-duty chassis whose pull skid has been reinforced. It also includes protections at the accesses for forklift. The drip tray can withstand 100% of the engine liquids.

To ensure impermeability, Himoinsa developed a new design for the doors whose upper face has an angle of 20 degrees. This prevents water filtration and oxidation points coming from an accumulation of stagnant water. The canopies of the S5 generator sets retain the rest of the components to withstand heavy rains and snowfall.

Himoinsa has incorporated a new layer in the process it follows to paint and protect metal parts. This involves a zinc-rich primer prior to the final finish that gives the canopy more than 1,500 hours of resistance to salt spray testing in accordance with ISO 12944. This classifies the protection level as C5 High. All the door locks and hinges are in stainless steel.

In order to reduce noise emissions even further, S5 generator sets incorporate a special rock wool insulation whose thickness in certain areas went from 50 mm to 100 mm. Components of different densities and characteristics are at the air inlets to reduce noise in a broad spectrum of frequencies. The company also changed the location and layout of the air inlets to mitigate noise.

New control and power panel

The S5 range includes a new control and power panel at the rear of the canopy which brings some advantages:

- It minimizes noise emissions. The panel is isolated from the engine room so there is no exposure to noise while the control unit is being handled.

- It facilitates maintenance. The user can replace the panels without having to remove the canopy.

- Versatility for use. The modular way allows different combinations of panels and electrical outlet configurations. The industrial bases can be replaced by powerlocks with a capacity of 100% of the power available in the genset.

- Accessibility and reduction of space. A replacement of the usual power outlet with a lower one that limits the total footprint of the genset and improves access.

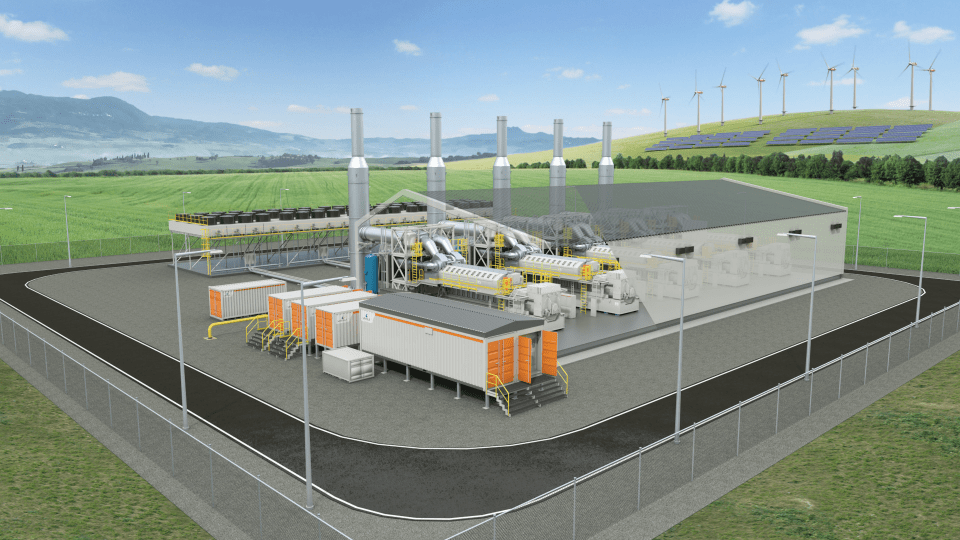

HIMOINSA 18 MW POWER PLANT FOR UK

S5 Running costs

S5 generator sets, mainly those with power greater than 80 kVA, guarantee running costs lower than those with Stage IIIA engines. Thanks to a significant reduction of fuel consumption. Most S5 models incorporate a new after-treatment system. In this way, the fuel consumption of the new engine is significantly lower, which ensures lower operating costs.

In parallel, Himoinsa made the fuel tanks of their S5 generator sets the same size as the AdBlue tank to match their fuel and urea running time, thereby further reducing running tasks and costs.