Lamborghini and CPL: trigeneration for the dreams

Lamborghini and CPL, an Italian due to set up a sustainable way to trigeneration. CPL Concordia was commissioned by the renowned car manufacturer to build the trigeneration plant that now contributes to lighting, heating and cooling what was once Ferruccio Lamborghini’s dream, and now a prominent company belonging to the Volkswagen group. As for CogenEurope, the […]

Lamborghini and CPL, an Italian due to set up a sustainable way to trigeneration. CPL Concordia was commissioned by the renowned car manufacturer to build the trigeneration plant that now contributes to lighting, heating and cooling what was once Ferruccio Lamborghini’s dream, and now a prominent company belonging to the Volkswagen group. As for CogenEurope, the European Association for the Promotion of Cogeneration chose Cpl and Lamborghini as winners of the Recognition Award 2019 in the Market Development (organizations) category. The awarding ceremony took place during Cogen Europe’s annual conference titled “Cogeneration: Efficient and Clean Heat and Power for Europe’s Sustainable Energy Future”.

Lamborghini and CPL Concordia. Who’s who

A few facts on CPL. Established in 1899, this cooperative offers multiple services mainly dealing with the management of heat (global service and facility management) gas (building, maintenance and operation of LNG and methane grids) and district heating, as well as with the development/application of renewable energy sources. They appear to have been active in cogeneration for some 30 years now; for the sake of precision, we asked them for more specifics. «We started our activities in cogeneration in the early ’90s” they said “with methane, biogas and diesel-fuelled plants. For natural gas we used the Totem (editor’s note: a pioneering cogenerator fitted with the same engine used on Fiat 127 cars – 903 cc, Over Head Valves) 15 Kw at 3000 rpm. Then we switched to bigger engines for landfill applications, all the way through to the current customized solutions reaching up to 100 Mw of power».

What are your engine suppliers of choice?

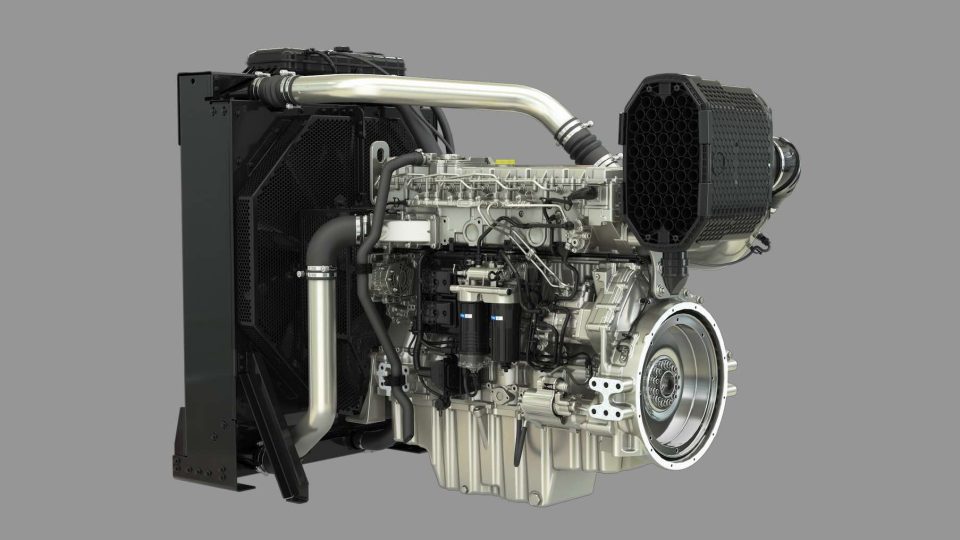

«We choose what we believe to be the most effective and efficient solution for our customers, which is why we work with all major players/manufacturers on the market. At Lamborghini, for instance, we installed a MWM plant for which we provide servicing directly».

Lamborghini and CPL: a couple fitted to Cogen Europe

He moves on to pinpoint the highlights of the award-winning plant. «The project that earned praise from Cogen Europe’s jury is made up of two elements: a trigeneration plant including two methane-fueled cogeneration units producing heat and power, coupled to two absorption chillers for cooling; plus a 6 km district heating network connecting the Lamborghini facilities to a biogas-to-energy cogeneration plant. Using the energy from the trigeneration plant and that recovered from the renewable-fuelled district heating grid, last year Automobili Lamborghini SpA managed to cover 34% of its own energy demand, saving a remarkable 1,4Ktep of primary energy. Moreover, the fact that the company resorted to cogeneration was a major contributor to it being the first company in the world to be certified as carbon-neutral under the Dnv Gl ‘Carbon Neutrality programme’».

Now a couple of words about the plant in operation at Lamborghini.

What are the features of the engines installed and which benefits do they bring about?

«The plant features two MWM cogen units with the same specifications and has a total electrical power output of 2.4 megawatts. Each year it generates approximately 20,000 MWhe. Both units are fitted with a V12, the same as in the Aventador LP 700-4, a jewel of the Sant’Agata Bolognese car manufacturing facility and a benchmark in the luxury supersport segment. Our technical/engineering choices were based on an analysis of the plant’s energy needs, to find a solution that could meet energy and environmental requirements alike by covering as much of the plant’s energy demand as possible while contributing to a maximum reduction of the environmental impact on the local territory. In terms of CO2 emissions avoided, indeed, the generation of energy as described earlier brings about savings totalling 1,640 tCO2/year.»