Liebherr and Cummins. A power(ful) relationship

Liebherr and Cummins. A good balance Liebherr and Cummins, another chapter in Liebherr’s strategy as a solution provider in power generation. A story that started some years ago. Do you remember the Diesel of the year 2017? The D9812 was chosen by Kohler-SDMO and took the name K175 Series, for the third bigger power generation […]

Liebherr and Cummins. A good balance

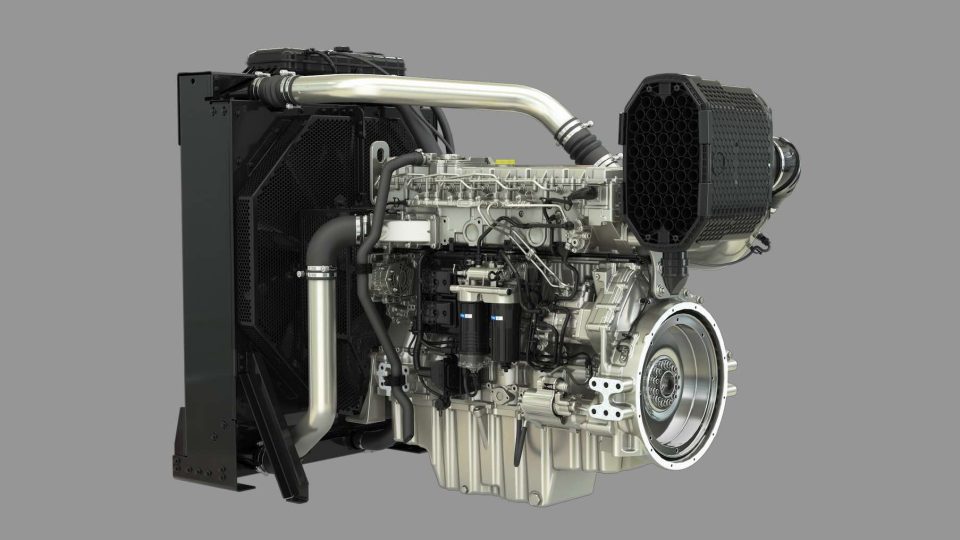

Liebherr and Cummins, another chapter in Liebherr’s strategy as a solution provider in power generation. A story that started some years ago. Do you remember the Diesel of the year 2017? The D9812 was chosen by Kohler-SDMO and took the name K175 Series, for the third bigger power generation player in the world.

WE WENT TO COLMAR, TO LIEBHERR FACILITY, WHERE D9812 IS MANUFACTURED

The Big Bang in Dubai

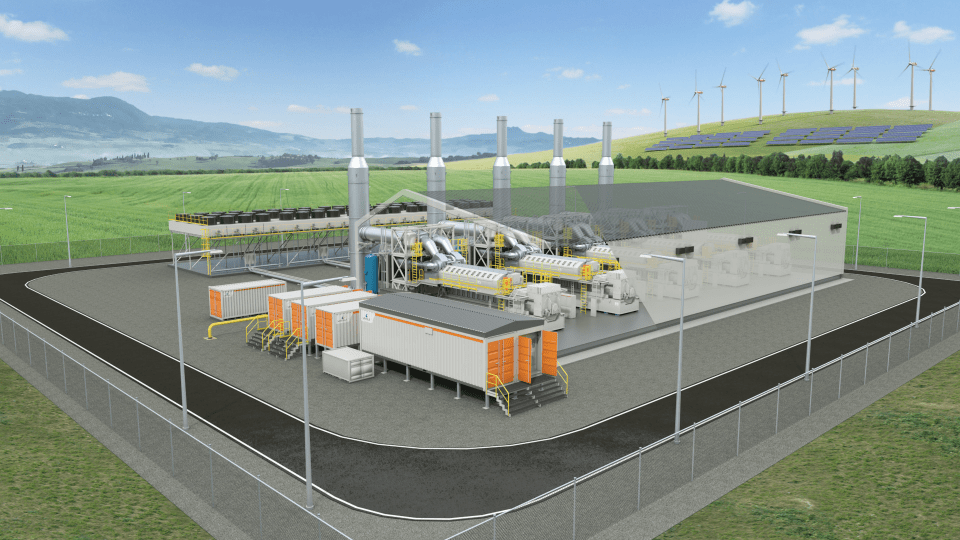

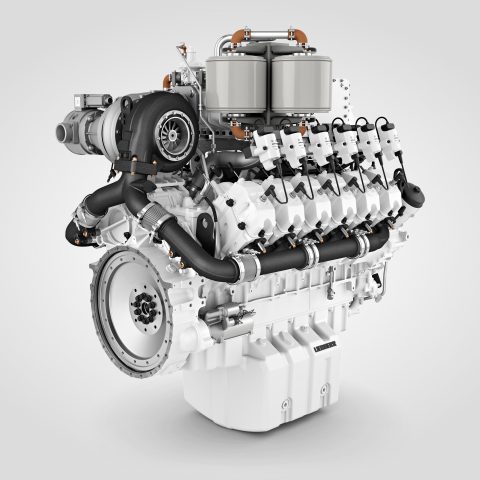

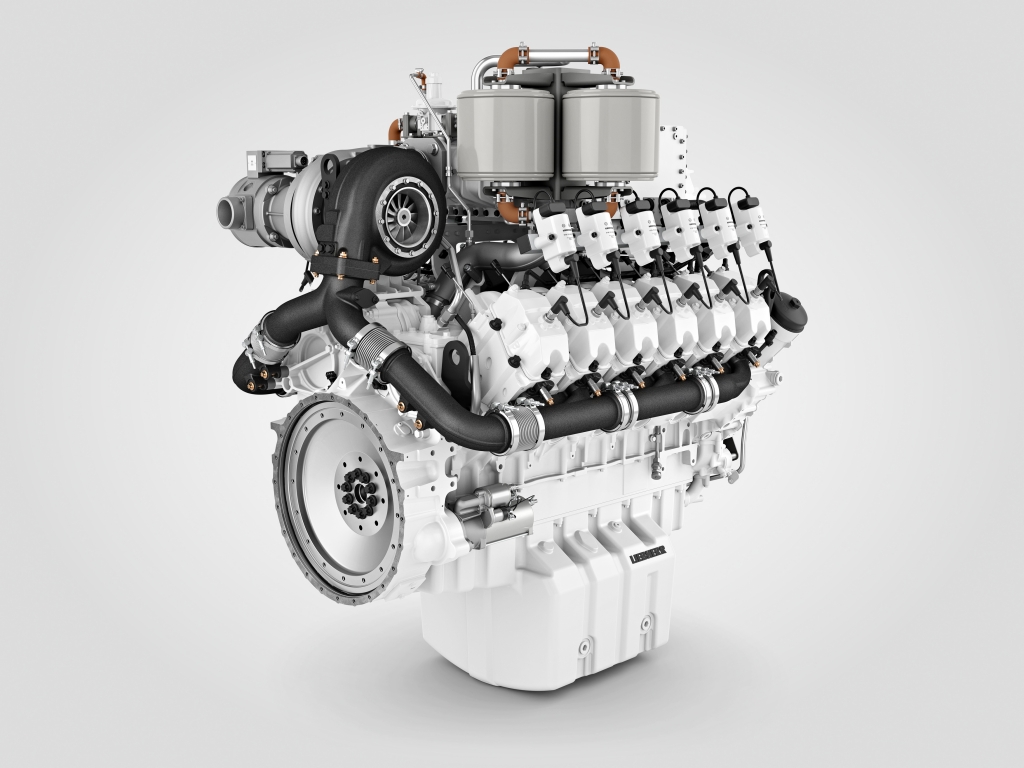

On Tuesday, March 3, at Middle East Energy in Dubai, the G25C was officially presented at the Cummins stand. We were at the Cummins plant in Ramsgate, UK for the C25G press preview and wrote about it in Diesel International issue 2, which you can download from diesel-international.com. Below are Liebherr’s point of view: “The Liebherr Components Division and Cummins Inc. start a cooperation in power generation. For the new Cummins C25G gas generator series, Liebherr will provide fully tested gas engines as complete ready-to-use equipment. It will include ignition and control system for natural gas and biogas applications in 50Hz and 60Hz markets. The C25G is designed to support any power need in different applications – from hospitals and industry to commercial building and utilities requiring reliable continuous operation, whether it is grid parallel or island mode.

The G9512, a 12-cylinder gas engine with 25 liters displacement, is developed and manufactured at the Liebherr facility in Bulle (Switzerland). The engine is the basis for the new Cummins C25G gas generator series. The latter will cover 500 kW@50Hz and 580 kW@60 Hz for combined heat and power (CHP/CCHP), demand side management and alternative fuel applications. Within the scope of supply, Liebherr-Components AG also delivers a control system to secure easy and reliable integration of the engine equipment into the C25G generator series. These systems are developed and assembled at the Liebherr facility in Biberach (Germany).

Some statements from Liebherr and Cummins

«A significant number of units are targeted to be in the field within the coming years. This will be a strong contribution to reduce CO2emissions worldwide by using overall high-efficiency equipment, as most engines will be operating in prime power (PRP) or continuous power (COP) mode for combined heat and power applications», explains Alejandro Held, Sales Director Power Generation at Liebherr-Components AG.

Liebherr expects to supply the first engine units already in 2020. Prototype and pre-series units have been tested commonly at Cummins facilities in the UK to validate the generator set configurations also in accordance with Grid Codes Compliance Standards.

«The new cooperation will enable us to not only serve the market with gensets and offer start-up, commissioning, preventive and corrective maintenance, but also handling of warranty based on the extended Cummins service network world-wide», said Chris Downs, Cummins Energy Management Marketing Leader.”