MAN Energy Solutions and Fonterra: partnership for heat pump technology

Fonterra and MAN Energy Solutions are entering a strategic partnership to reduce CO2 emissions in dairy production using climate-friendly heat pump technology for steam generation.

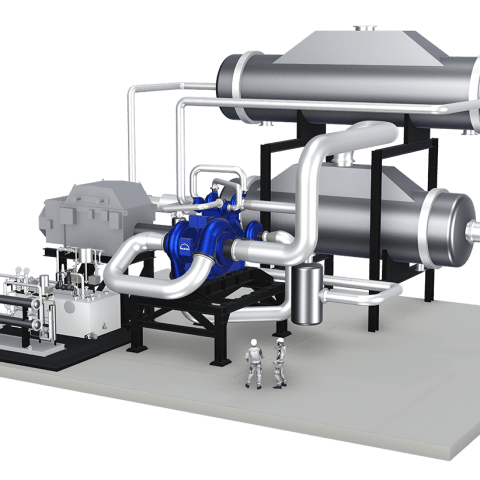

The partnership between Fonterra, a global dairy nutrition Co-operative located in New Zealand, and MAN Energy Solutions will trial the design and implementation of an industrial-scale heat pump technology to replace non-renewable energy in raising steam. This project could result in a reduction of 60,000 metric tons of CO2 annually for the Co-operative, the equivalent of taking 25,000 cars off New Zealand roads.

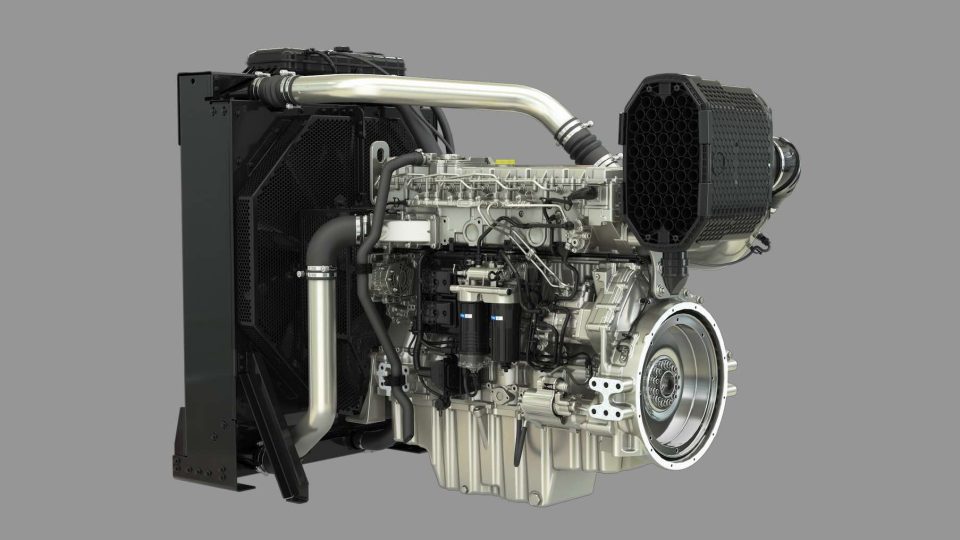

Powered by electricity, the high temperature MAN Heat Pump solution would allow Fonterra to produce steam to dry dairy ingredients using renewable electricity from sources such as hydro, solar, geothermal and wind. After integration into Fonterra’s production infrastructure, the heat pump could produce more than 30 metric tons of process steam per hour, equivalent to a thermal output of 25 megawatts.

The first step will be to carry out an engineering study to develop the integration of the heat pump solution into the Co-operative’s existing milk powder production. This study is expected to be completed by the end of April 2023. The findings will then be used to design a heat pump system at one of Fonterra’s manufacturing sites.

Fonterra Chief Operating Officer Fraser Whineray says: “Improving energy efficiency and trying a range of fuels in our manufacturing operations remains a vital part of our decarbonisation strategy. We’re working to meet the expectations of our customers, consumers, and stakeholders here in New Zealand and around the world, who are increasingly wanting us to accelerate progress to reduce our emissions. A key contributor to this reduction is the Co-operative’s transition away from coal by 2037. By the end of the year, it is expected that only six out of 29 sites will be using coal. We see huge value in collaborating with innovative partners to achieve this ambitious goal. MAN Energy Solutions will provide a resilient and efficient Heat Pump solution for our sites producing nutrient-rich dairy products.”

Uwe Lauber, CEO of MAN Energy Solutions, says: “We have put technology solutions to lower greenhouse gas emissions from industry at the heart of our strategy. MAN’s heat pump technology brings the economic and climate-friendly benefits of heat pumps to a crucial sector such as the food and beverage industry. With Fonterra being the third biggest milk ingredient producer in the world, we are very much looking forward to supporting their decarbonisation journey with our expertise and cutting-edge technology solutions. Innovations that arise from such strong partnerships are key in the decarbonisation of industrial processes.”

The heat pump project is a result of work to find innovative energy solutions between Fonterra and its engineering partner Aurecon to support the Co-operative’s long-term commitment to sustainability. Fonterra has an ambition to be at net zero emissions by 2050 with an interim target of a 30% absolute reduction in manufacturing emissions by 2030 based on its FY18 level.

Last year the Co-operative announced the installation of a biomass boiler to replace a coal boiler at its Waitoa site in the Waikato region, this is expected to be up and running in November 2023. Similar sustainable fuel switching projects have taken place at Fonterra’s Te Awamutu and Stirling sites. The latter is due to be operational in April this year.