Cutting-edge heat generation: MAN ES ETES heat-pump system to be delivered in Denmark

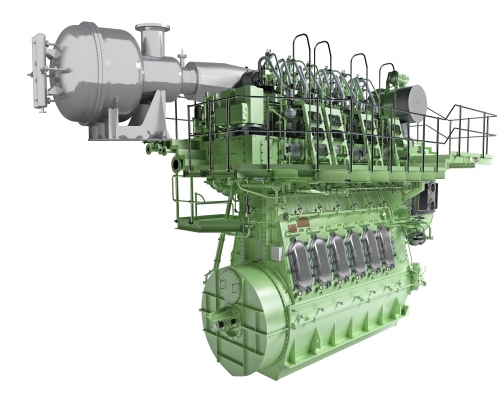

Danish multi-utility company, DIN Forsyning, has commissioned MAN Energy Solutions to supply a turnkey technology solution for heat generation, featuring two ETES heat-pump systems. These will be installed in a new district heating plant based on the operating principle of a heat pump – but on a large, industrial scale. With an overall heating capacity […]

Danish multi-utility company, DIN Forsyning, has commissioned MAN Energy Solutions to supply a turnkey technology solution for heat generation, featuring two ETES heat-pump systems. These will be installed in a new district heating plant based on the operating principle of a heat pump – but on a large, industrial scale. With an overall heating capacity of 50 MW, the plant will supply around 100,000 local inhabitants with approximately 235,000 MWh of heat annually.

The location at the Port of Esbjerg will enable the use of renewable power from nearby wind farms and seawater as a heat source for the generation of heating energy. The new district-heating plant will thus guarantee an emission-free alternative to the city’s current, coal-fired power plant, which at present provides approximately half of Esbjerg’s district heating and is scheduled for closure by April 2023.

MAN ES ETES heat-pump system for carbon neutrality

«Esbjerg has very ambitious goals to become carbon neutral by 2030, and the new heat pump will be an important element in achieving this. Esbjerg City is undergoing a huge change these years and transforming a carbon industry towards a world leading position as a green city», explained Jesper Frost Rasmussen, Mayor of Esbjerg.

«The transition to a carbon-neutral world is at the core of all the actions we take today. This is why we are very proud to play a major role in the pioneering Esbjerg project as the provider of an innovative technology solution. The ETES heat-pump system is a climate-neutral alternative to traditional, large-scale heat supplies and will significantly drive the decarbonisation of the heating sector», stated Uwe Lauber, CEO of MAN Energy Solutions.

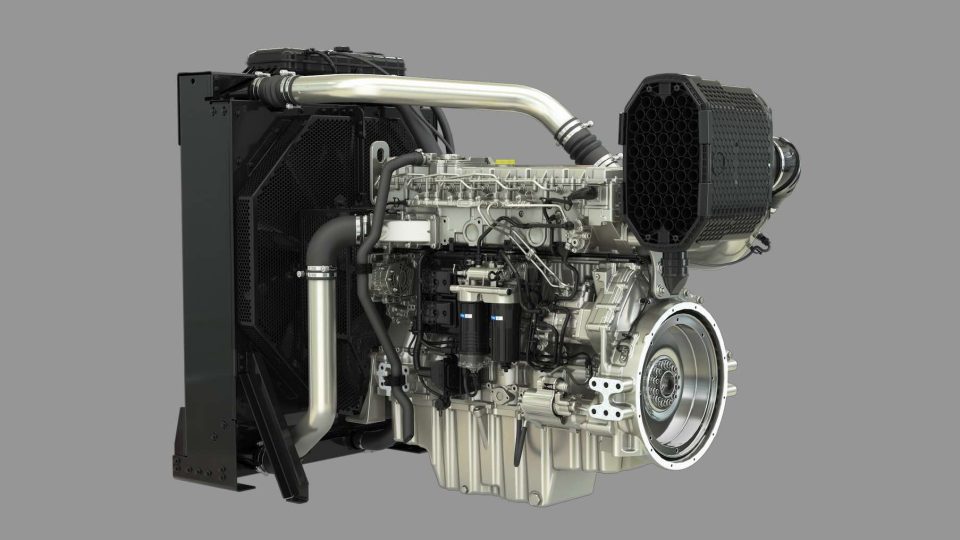

Three MAN 6L23/30H Mk3 gensets on the road to Daehan shipbuilding

Moving to the sea, STX Engine has signed a contract with Daehan shipbuilding for three MAN 6L23/30H Mk3 gensets for 1+1 vessels, which marks the first sale of the engine’s Mk3 version. The engines are bound for an Aframax crude tanker ordered by Atlas Maritime, the Greek international shipping company, and will achieve Tier III emission levels with the aid of SCR. They are provisionally scheduled for delivery in August 2021.

Finn Fjeldhøj, Head of Small-Bore, Four-Stroke Engineering, MAN Energy Solutions, said: «This is an important order; our 23/30H GenSet is a proven workhorse that our customers have much appreciated over the past half-century, and whose new mark now prepares it for the next many years in the market».

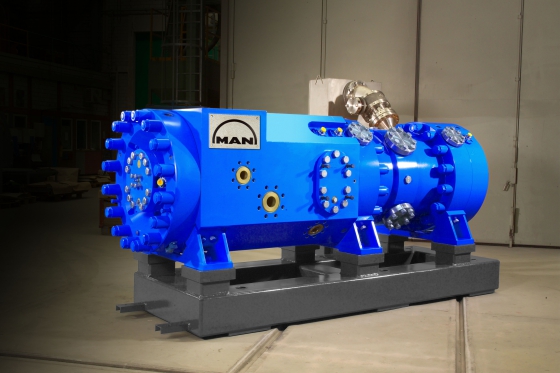

Tier III exhaust-after-treatment orders for low-speed engines Pass 1,000 mark

Last but not least, MAN Energy Solutions’ Two-Stroke Business has announced that it has surpassed 1,000 orders for secondary-measure, Tier III-compliant, emission-reduction technology for its portfolio of MAN B&W-branded, low-speed engines.

Approximately one-quarter of the orders have been for EGR systems, with SCR systems accounting for the remainder. The milestone was passed in early-January 2021 and is built upon references from the company’s portfolio of ME-B, ME-C and MC- C fuel-oil engines. Currently, almost half of all orders have entered active service.