MTU microgrid solutions for agriculture

MTU microgrid for farming applications. The participation of Rolls-Royce and its MTU brand at Agritechnica focused on two major issues. In addition to the latest achievements on the Stage V certification for industrial engines, the Friedrichshafen company put a lot of efforts on the eco-friendly and on-site power generation solution suitable for agricultural applications. In […]

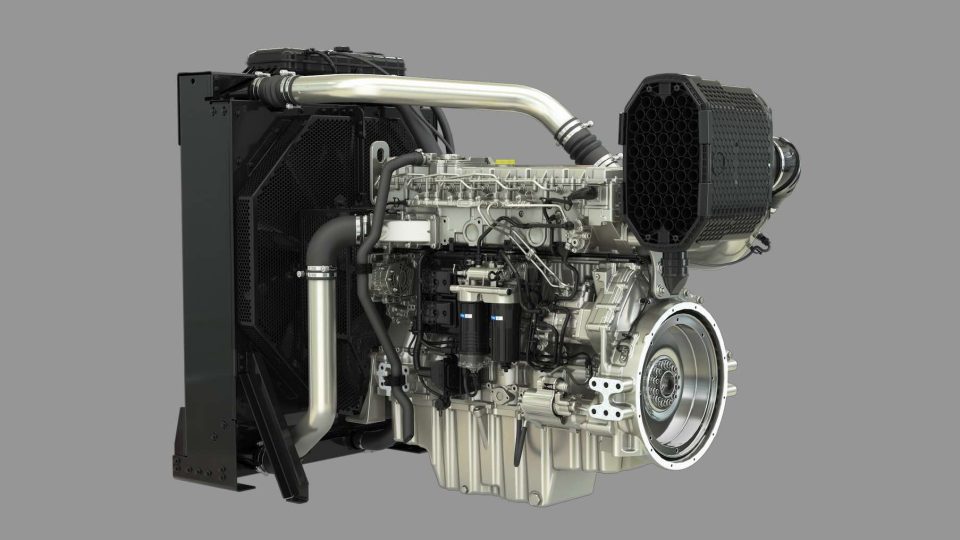

MTU microgrid for farming applications. The participation of Rolls-Royce and its MTU brand at Agritechnica focused on two major issues. In addition to the latest achievements on the Stage V certification for industrial engines, the Friedrichshafen company put a lot of efforts on the eco-friendly and on-site power generation solution suitable for agricultural applications. In other words, microgrids.

MTU microgrid control system

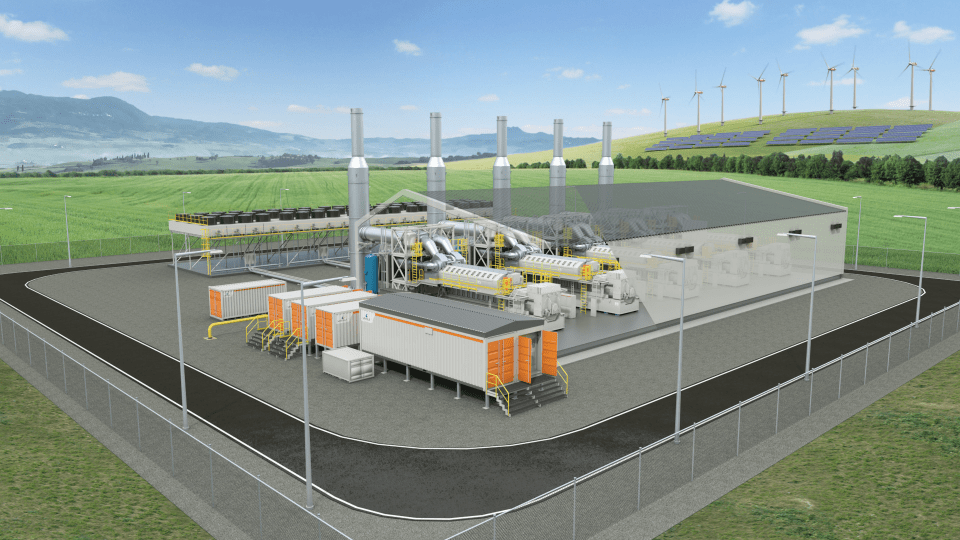

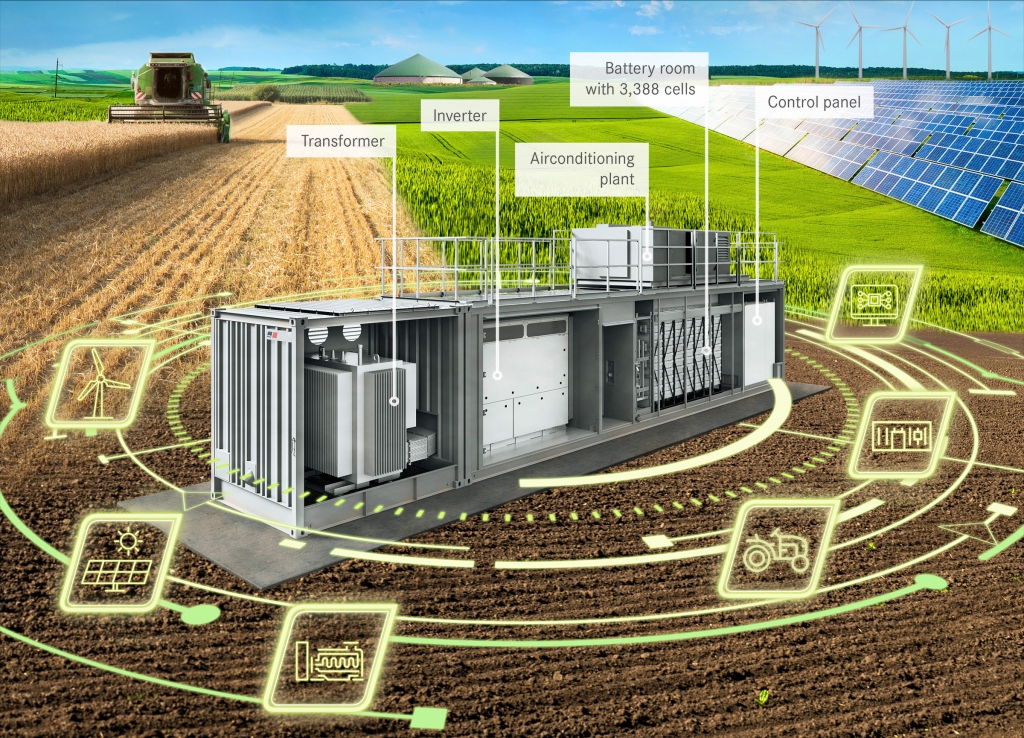

These autonomous power grids combine renewable energy sources with battery storage and gas and diesel generators using a microgrid control system developed by Rolls-Royce, thereby reducing C02emissions in power generation. Farmers also lose their dependency on the public grid and can integrate existing energy sources such as photovoltaics or biogas plants, which offers financial benefits.

«Many farmers already have large-scale photovoltaic or biogas plants and are therefore ideally equipped to use a microgrid. Our MTU EnergyPack, the battery container, and a smart energy management system allow the various energy sources to be optimally deployed, both technically and in terms of cost», explains Cordelia Thielitz, Vice President Microgrids at Rolls-Royce.

The components of a microgrid can be adapted according to the requirements. The possible applications in agriculture are manifold and offer advantages in terms of return-on-investment (ROI), decentralisation and decarbonisation.

A couple of practical examples

Instead of continually pumping all the electrical power won from a biogas plant into the public grid, it can be stored in the MTU-EnergyPack. The smart energy management system then ensures that this energy is only fed into the public grid at times of peak demand, when prices are at their highest.

As for self-sufficient greenhouses, to flourish and grow, crops cultivated in greenhouses need temperature levels and light exposure to be kept as constant as possible. The heat and power required to achieve that constitute major cost factors for any farmer.

QUITE A GOOD TIME FOR ROLLS-ROYCE POWER SYSTEMS

But with combined power generation using a photovoltaic installation and MTU generator linked up to a battery and master controller, the greenhouse can operate independently round-the-clock without recourse to the public grid. Electrical energy generated by photovoltaics and a gas-powered CHP module during the day can be fed into the batteries, where it is subsequently available for lighting the crops and other electrical consumers.