Piller and the kinetic energy storage: a century of continuity

The years are 110, to be precise. It was 1909 when engineer Anton Piller founded the company named Piller. Today, the German company is quite a benchmark in the field of rotary UPS, employs currently about 1,000 people worldwide and has its headquarters in the city of Osterode, near Hanover, as well as subsidiaries throughout […]

The years are 110, to be precise. It was 1909 when engineer Anton Piller founded the company named Piller. Today, the German company is quite a benchmark in the field of rotary UPS, employs currently about 1,000 people worldwide and has its headquarters in the city of Osterode, near Hanover, as well as subsidiaries throughout Europe, America, Asia and Oceania.

UPS systems are continuous power supplies that, instead of using batteries (but there are also those in the catalog) ensure continuity to the network by skillfully coupling rotary masses and motor alternators.

THE VERY FIRST EDITION OF DPE RIMINI

Record-breaking reliability

In this way, in the event of a power failure, the power supply can be guaranteed for a minute or so without any interruption. Just enough time to allow the generators or other systems to intervene.

And it is done by exploiting the kinetic energy (like the Perkins hybrid) of masses kept in rotation. Reliability is paramount, always higher than 97-98% as it is, with a bit of maintenance, the duration in time.

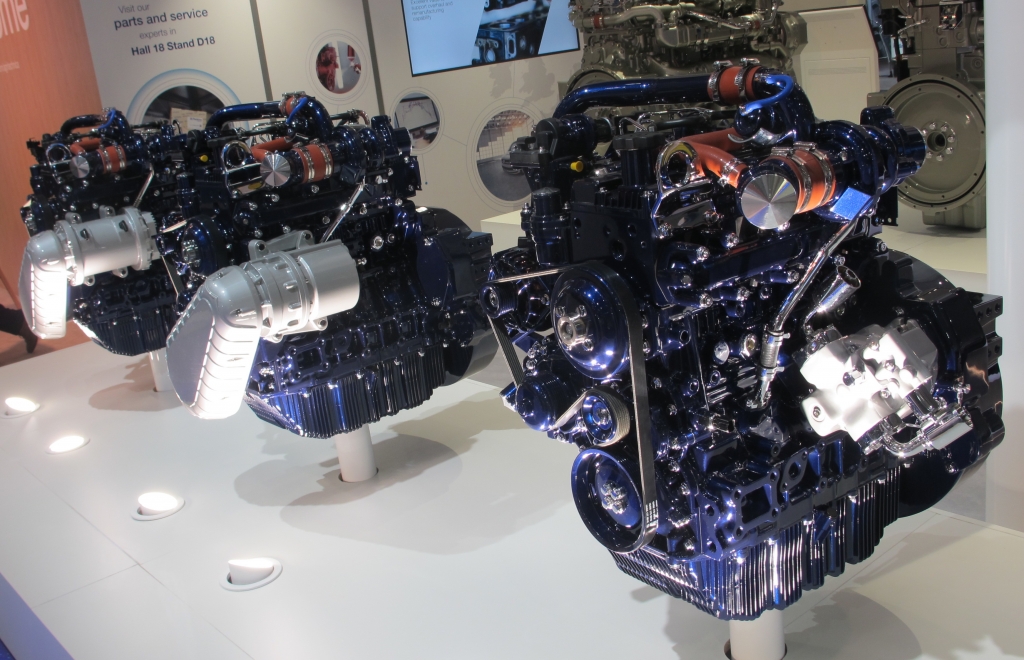

Piller systems: the power range

The systems provided range from 150 kVA to 50 MVA, powers obtained by combining individual machines of smaller size. The Critical Power Module (CPM) oversees the operation, in a combination of nearly infinite operating modes.

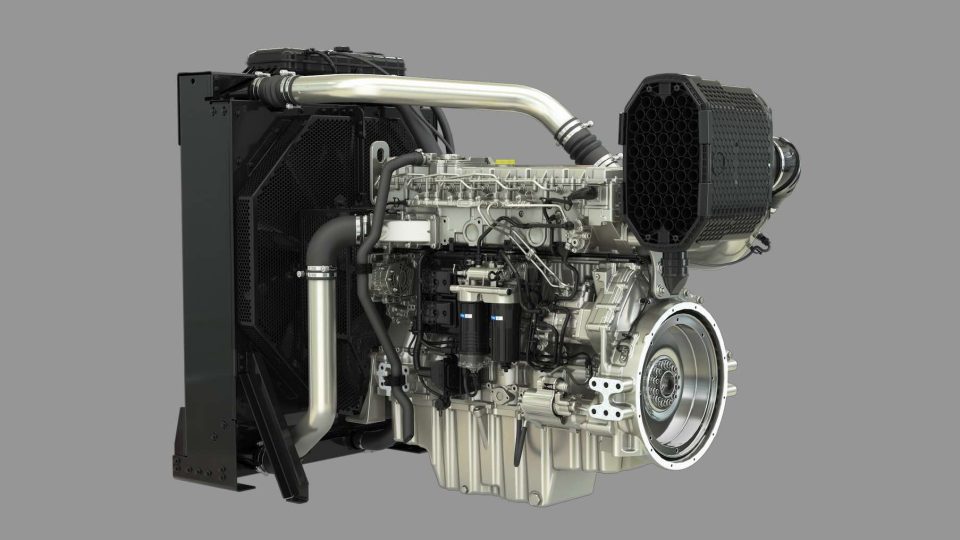

PERKINS ‘HYBRID SURPRISE’ AT BAUMA

And if 60 seconds are not enough, there is always the possibility to combine a diesel engine, obtaining the so-called infinite reserve.