Rolls-Royce opens powerpack remanufacturing workshop in Brazil

Rolls-Royce has expanded its capabilities in Brazil to include a new remanufacturing centre for the overhaul of mtu Kinetic PowerPacks (KPP) at its facility in Sao Paulo.

Rolls-Royce has expanded its capabilities in Brazil to include a new remanufacturing centre for the overhaul of mtu Kinetic PowerPacks (KPP) at its facility in Sao Paulo.

Jörg Stratmann, CEO of Rolls-Royce Power Systems, said at the opening in Sao Paolo: “With this expansion, we are investing in our presence and our service in the dynamically growing Brazilian and Latin American market, to continue to stand by our customers as a strong and reliable partner. With mtu Kinetic PowerPacks, we are securing critical infrastructure and providing a reliable energy solution as the backbone of the increasing digital industry”.

The workshop, integrated within the existing plant, includes specialized overhaul areas, a test bench, and a control room. Overhaul operations have already commenced, with seven mtu Kinetic PowerPacks successfully refurbished and tested to date for customers in Brazil. In the long term, the facility aims to handle up to 30 dynamic uninterruptible power supply systems (DUPS) annually.

Currently, approximately 150 mtu Kinetic PowerPacks are operational in Brazil, serving critical sectors such as data centres, food and beverage production, and the pharmaceutical industry—particularly in vaccine production. The systems ensure an uninterruptible power supply and secure operations even during power outages. mtu Kinetic PowerPacks require only routine maintenance for the first 10 years of life, at which point they are overhauled. Unlike static uninterruptible power supply systems (UPS) that include batteries with a standard lifespan of five years, dynamic UPS systems such as the mtu Kinetic PowerPack have a lifespan of 20+ years.

“With the new facility, we are implementing our strategy of offering our customers in Brazil an even better and more sustainable service,” said Bernard Hanssens, head of global service at the Rolls-Royce competence centre in Liege, Belgium. Larissa Frausto, supply chain director in Brazil, added, “By overhauling locally, we’re reducing both logistics costs and the environmental impact, while promoting further technical development of our local workforce.”

So far, mtu Kinetic PowerPacks have been shipped to Belgium for overhaul. By shifting these operations to Brazil, Rolls-Royce not only improves turnaround times but also significantly cuts CO2 emissions associated with international transport.

How mtu Kinetic PowerPacks work

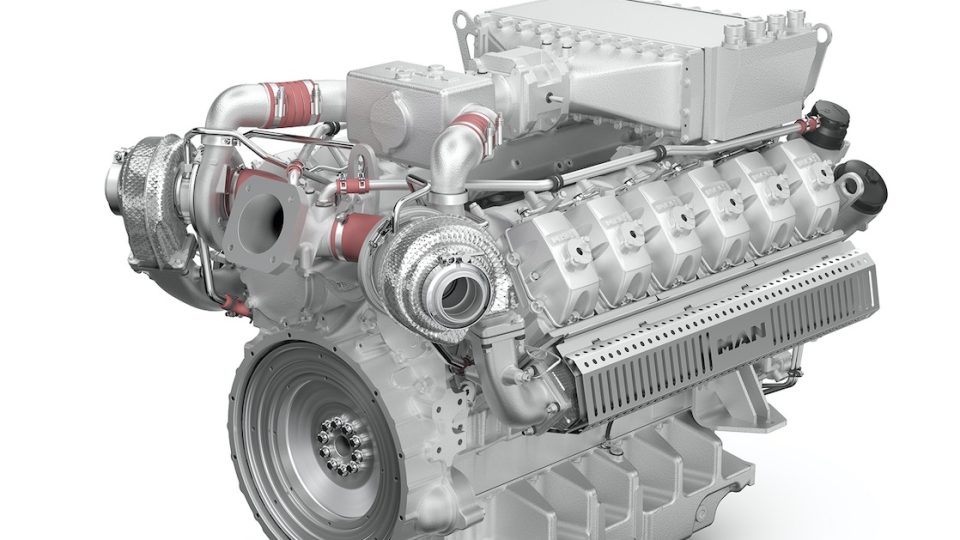

Each mtu Kinetic PowerPack includes a rotating kinetic energy storage unit, an mtu diesel engine, and a generator that also functions as an electric motor, alongside a specialized control system and switchgear with a throttle that filters power from the main grid. The kinetic mass storage device is charged by the synchronous generator, which runs as a motor while connected to the grid. It stores energy that is released instantly in the event of a power failure, ensuring seamless power continuity. Thus, the mtu Kinetic PowerPack offers both power conditioning and uninterrupted power supply.

Read also: Rolls-Royce remanufactures 170 mtu rail PowerPacks for Netinera trains