Strucinspect and Voith Hydro: the dam in view

Strucinspect and Voith Hydro are using digital inspection technology on a dam in a pilot project, in the Scottish power station Clunie.

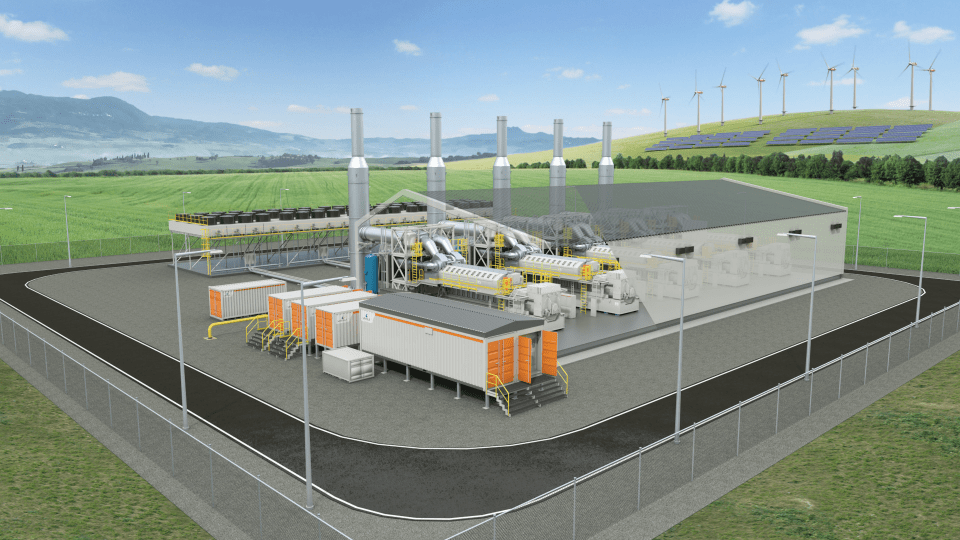

Hydroelectric power plants account for 16 percent of electricity generation worldwide. For centuries they have been among the most reliable energy producers in the form of storage and run-of-river power plants. In order to optimize their potential and maximize their service life, it is important to keep the structures, pipelines and turbines in top condition. This is exactly the challenge that Strucinspect and one of the world’s largest supplier of hydropower equipment, Voith Hydro, are facing together. In a pilot project in 2022, the Scottish power plant Clunie was put through its paces.

“Clunie is 72 years old and, in terms of capacity and size, the heart of SSE Renewables’ chain of power plants between Dalwhinnie, Rannoch and Pitlochry,” explains Andrea Venora, Head of Project Sense at Voith Hydro. This is a gravity dam where the forces of the horizontal water pressure, the brine pressure and the mass of the structure meet. “So far, the inspections in Clunie are carried out twice a year in the form of walk-throughs of the entire structure,” states Albrecht Karlusch, Managing Director of Strucinspect. A severe problem would arise if not all the damage were detected in time. “This is where the advantages of our digital inspection technology come into their own,” emphasizes Karlusch.

Customized solutions for optimal maintenance

The Viennese start-up, founded in 2019 as a joint venture between Palfinger AG, VCE and the Angst Group, uses data collected by drones to efficiently visualize and analyze them with the help of artificial intelligence and other technologies such as Building Information Modeling (BIM) or Augmented Reality (AR). Based on a set of configurable technology modules, Strucinspect develops individual business solutions together with its customers in order to capture and precisely record inspection data, process it efficiently and use it for effective maintenance decisions.

New services through strategic partnership

An interesting partnership for the global technology group Voith, which has been equipping hydroelectric power plants with components for over 150 years. The product and service portfolio of its Hydro division includes generators, turbines and pumps, measurement-, regulation- and control systems, as well as service and maintenance. “Strucinspect’s digital inspection technology opens up the opportunity to offer new services globally. It is making digital assessment and tracking of civil conditions easier and safer,” says Voith Hydro CTO, Norbert Riedel.There are thousands of dams with an average age of 50 years worldwide and many other assets like penstocks, power houses and tunnels that this technology can be used at. “Maintenance and inspection there become more precise and efficient through the use of our technology, downtimes are reduced, and the performance of the plant is ensured,” describes Karlusch the advantages of digital inspection.