The Perkins 5012 at the Middle East Energy

At the Middle East Energy Perkins is introducing the new 5012, the latest electronic 5000 Series engine optimised and purpose built for power generation applications.

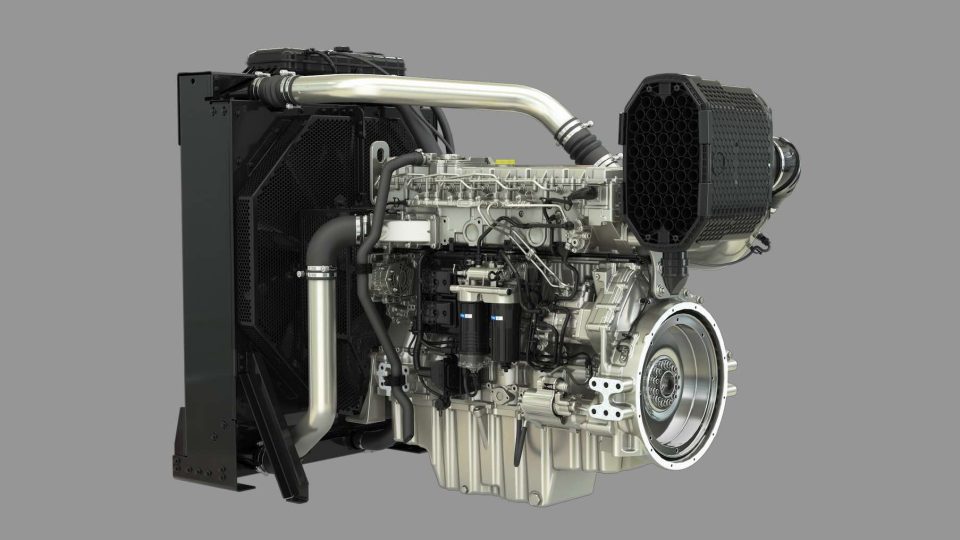

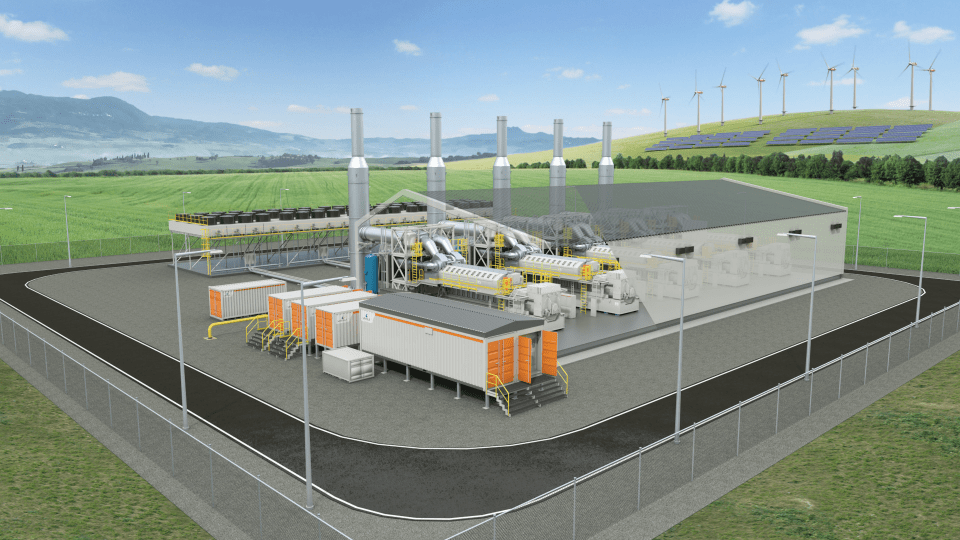

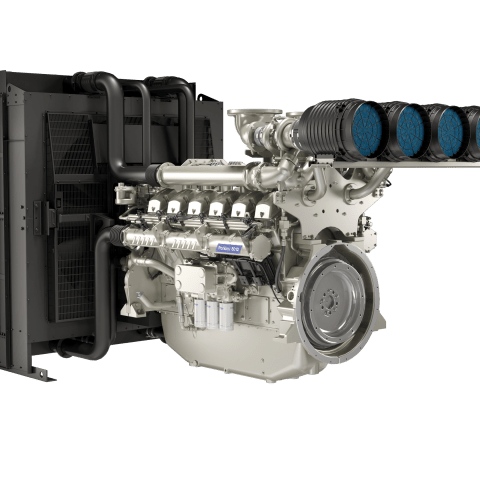

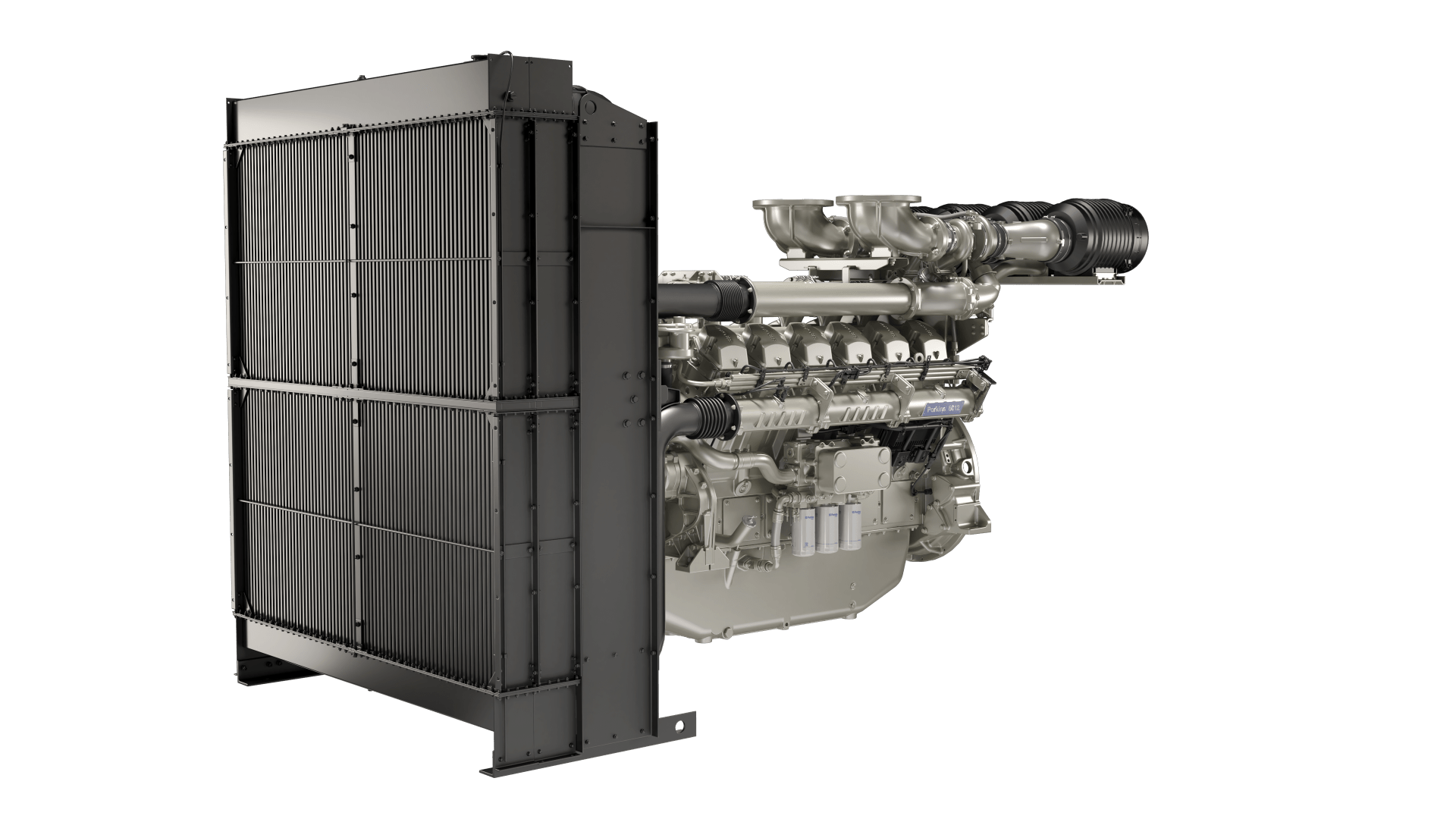

At the Middle East Energy Perkins is introducing the 5012, the latest electronic 5000 Series engine optimised and purpose built for power generation applications. Offering 1275 to 1710 kVA for 50 Hz prime applications and 1250 to 1500 kW as a 60 Hz critical standby power plant, the engine features a V12 configuration in a compact package, making it ideal for hospitals, data centres and other locations where space is limited.

Perkins is also unveiling an expanded suite of connectivity solutions for its electric power applications, including Application Programming Interface (API) for original equipment manufacturers’ (OEMs) who already have their own telemetry solutions, as well as an easy-to-connect Perkins telematics offering. For both solutions Perkins can provide condition monitoring and seamlessly exchange enhanced insights with OEMs and customers.

“Construction projects in the Middle East are adopting fresh approaches and leading-edge technologies to drive economic development infused with sustainability,” said Jaz Gill, Vice President of Perkins global sales marketing, service and parts. “The expansion of our highest performing engine series shows how we’re leveraging our culture of innovation and agility to support progress through the energy transition.”

Perkins 5012 engine optimised for power generation

The Perkins 5012 is the latest offering in the 5000 Series of engines built to world-class standards for high efficiency, low fuel consumption and global emission standards. Available later this year, the new engine is certified as U.S. EPA Tier 2 compliant. It is also Tier 2 capable outside the U.S. and is offered as a fuel optimised (unregulated) model.

The 5012 is engineered to meet ISO G3 and NFPA110 standards to handle demanding load acceptance challenges. It uses a pair of smaller turbochargers on each bank that reduce transient response time when compared with a single large unit. Its exhaust manifolds are engineered to optimise gas flow to the turbochargers, further reducing ramp-up time and enhancing load acceptance.

The engine uses a unique low-pressure fuel system developed specifically for the 5000 Series that is more tolerant of variations in fuel quality. For generator manufacturers and end users looking to reduce their greenhouse gas emissions, the 5012 can run with biodiesel up to B20 based on a 20 percent dilution of biodiesel with standard diesel or on 100 percent hydrotreated vegetable oil (HVO).

The 5012 is a purpose-designed engine optimised with the latest technology to operate at top efficiency over its full rated output range. It is physically smaller than legacy engines offering similar power output, making it an ideal choice for space-limited applications.

Electronically controlled injectors used on the 5012 can alter both timing and pressure to accommodate a broad range of ambient temperatures and altitudes without sacrificing performance. Working together with the advanced turbocharging technology developed for the 5000 Series the combination has been proven to help optimise load acceptance, altitude capability and fuel consumption.

The 5012 engine is also equipped with an electric fuel priming pump and premium fuel and oil filters to achieve an oil and fuel service interval up to 500 hours or two full years.