Volvo Penta and the BESS subsystems

Volvo Penta is carving out a space in the battery energy storage systems sector as a battery supplier of purpose-built subsystems that prioritize energy density and adapt to various BESS requirements. With ready-to-deliver subsystems, Volvo Penta is ready to support companies in developing resilient and tailored solutions, thus potentially playing a part in different energy transition strategies.

Volvo Penta ’s purpose-built battery energy storage systems (BESS) solutions complement standard approaches, offering unique strengths that cater to varying BESS scenarios where energy density is a priority, in segments such as construction, ports, and data centers.

With comprehensive lifecycle support, Volvo Penta aims to ensure seamless integration and operational reliability through tailored application guidance, service agreements, and other solutions such as remote monitoring and recycling programs. Volvo Penta works alongside original equipment manufacturers (OEMs) to deliver tailored battery solutions that meet the customer’s energy demands that address spatial limitations, transportability, and energy density.

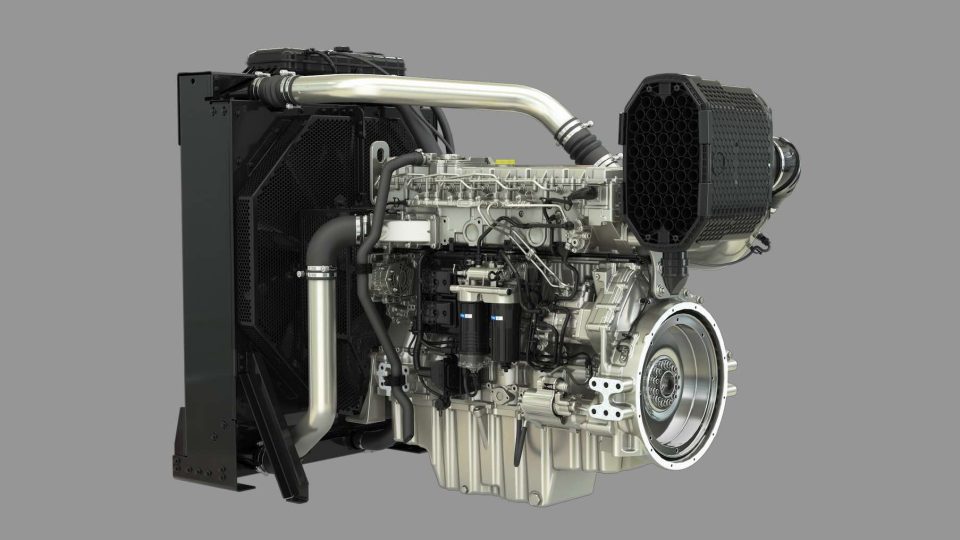

What’s in Volvo Penta’s BESS subsystem?

A key part of being a system supplier, Volvo Penta lends extensive application support to help customers right fit their BESS subsystem for efficient energy storage in stationary and mobile applications. The subsystem features an energy-dense battery pack with a favorable C-rate to support fast charging and discharging, along with a robust battery management system (BMS) that is aimed at optimizing performance, battery longevity, and even cybersecurity.

Key components in the subsystem include a DC/DC converter for auxiliary power, a telematics gateway for real-time monitoring, and a thermal management system to maintain optimal battery performance in various environments. Electrical safety is ensured through high-voltage isolation monitoring and other protective features.

The CAN and DC interfaces, adapted from the Volvo Group’s platforms, ensure reliable data transfer and system optimization. Volvo Penta’s subsystem handles the DC portion of the BESS, while the OEM is responsible for the container shell, AC componentry, and set up, ensuring the system is tailored for the intended applications.

Volvo Penta’s BESS subsystem is also designed to withstand tough environments, offering robust protection against dust and corrosion for reliable performance in challenging conditions. With ingress protection (IP) ratings and corrosion-resistant materials, it is built for durability and dependability in tough environments.

Volvo Penta custom-built systems are designed to meet diverse energy needs, for peak shaving, supporting a microgrid, or to ensure uninterrupted power.

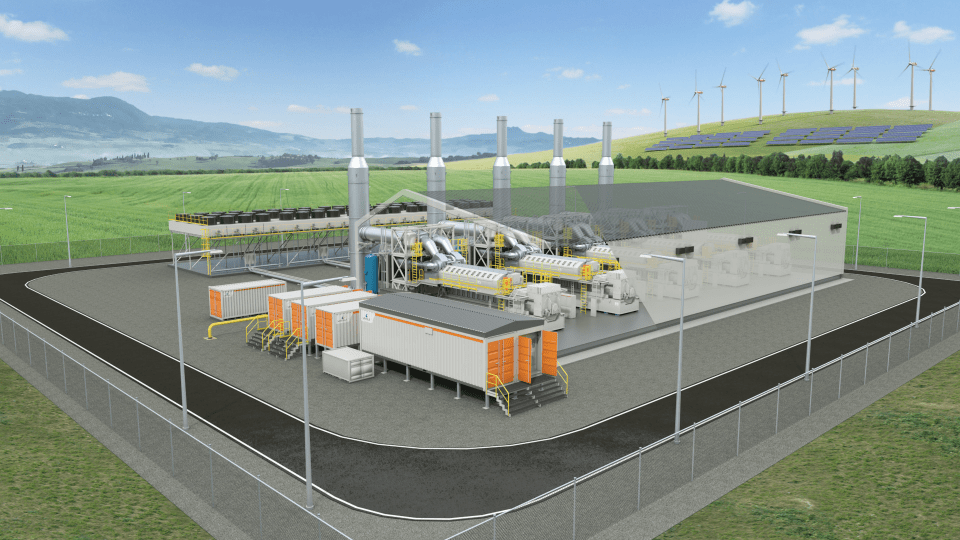

Microgrids

As industries like ports and quarries experience growing energy demands that surpass grid capacity or where there is limited grid connectivity, Volvo Penta’s energy-dense BESS offers a powerful opportunity. Volvo Penta-powered BESS can integrate with renewables or other power generation assets, to provide more stable and reliable energy essential for large-scale or remote operations transitioning to electrification.

With an energy-dense design ideal for mobile applications, Volvo Penta’s containerized BESS is perfectly suited for no-emission zones or remote locations where electric machinery requires charging. The BESS can be transported to the site to power operations from large festivals to disaster relief. Once discharged it can be relocated to an on-grid area for recharging – all while ensuring uninterrupted activity at the site.

BEV charging support

Volvo Penta’s battery energy storage subsystem is expertly designed to support grid stability in demanding applications such as construction and port operations, where capacity and frequency challenges often arise during electrification. With its robust IP classification, the system delivers reliable performance even in the harsh and challenging conditions typical of these industries.

Data Centers

Critical for ensuring uninterrupted operations, the subsystem’s robust Battery Management System (BMS) and rapid discharge capabilities deliver performance tailored to data centers. Their compact size allows for efficient integration into facilities where space is a premium, including industrial hubs.

Backup Power

Designed to provide instant, dependable backup power, Volvo Penta’s subsystems are ideal for the public sector (military or hospitals), or residential and logistics (cold storage), where continuous operation is non-negotiable, even during grid outages.

Commercial Buildings

Perfect for urban settings or high-demand industrial sectors such as manufacturing and population-dense residential areas, the compact, energy-dense design supports peak shaving and load balancing, and can help to reduce energy costs in these spaces.

Production-ready

Volvo Penta’s BESS subsystems have entered the industrialization phase after extensive testing and prototyping with customers. With production capabilities established, Volvo Penta is ready to engage with manufacturers, system integrators, and customers to co-develop solutions that address their high energy requirements. As industries move toward greater electrification and sustainability, Volvo Penta leverages its global footprint and end-to-end lifecycle support to deliver high-performance, customizable, and resilient subsystems. Through its OEM and distribution networks, the company provides application expertise, service contracts, recycling solutions, and remote monitoring to help customers optimize energy usage and achieve sustainable, efficient operations.