Wärtsilä and sustainable power: the ICE way

We’re going to talk about Wärtsilä and sustainable power. The first case study is based in China, the second one in Germany. Let’s start with Huaneng Jiangsu Co, the provincial subsidiary of China Huaneng Group Co., Ltd that is one of China’s largest state-owned power generation companies. Wärtsilä and sustainable power in China “They have signed […]

We’re going to talk about Wärtsilä and sustainable power. The first case study is based in China, the second one in Germany. Let’s start with Huaneng Jiangsu Co, the provincial subsidiary of China Huaneng Group Co., Ltd that is one of China’s largest state-owned power generation companies.

Wärtsilä and sustainable power in China

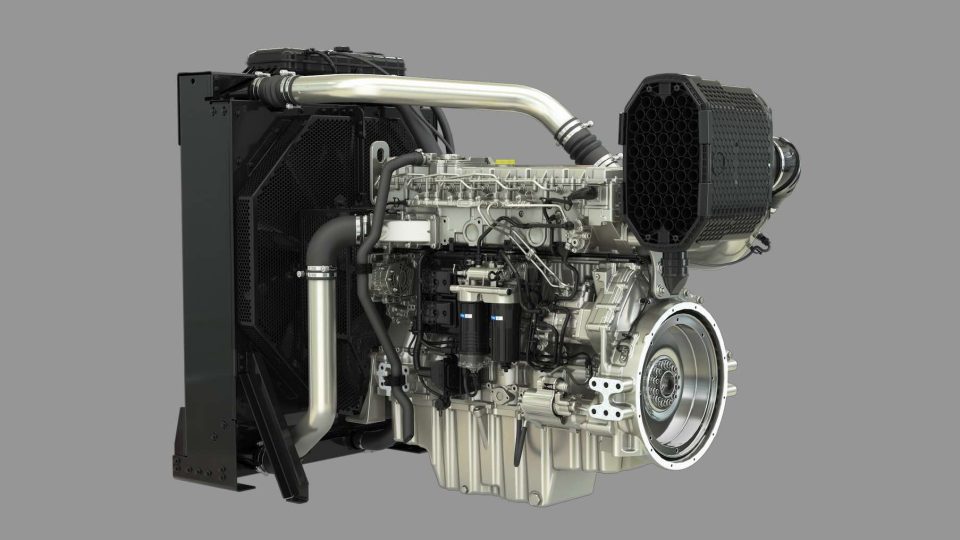

“They have signed a Strategic Cooperation Framework Agreement to cooperate in the development of sustainable power generation in Jiangsu, China. The agreement was signed at the Huaneng Jiangsu company headquarters on 31 December 2020. The aim of the Cooperation Agreement is to develop more sustainable and flexible power generation based on internal combustion engine technology (i.e neutral synthetic biogas? Yes, in Finland!) that would enable the integration of more renewable resources into the Jiangsu grid. This aligns with China’s energy security strategy of ‘four revolutions and one cooperation.’ The strategy’s four revolutions are intended to curb energy consumption, establish a diversified energy supply system, upgrade energy technology, and speed energy sector development. The cooperation aspect refers to strengthening international cooperation to achieve energy security under open conditions.

Wärtsilä’s long-term R&D commitment on improving combustion engine efficiency has resulted in Wärtsilä engines having the highest efficiency numbers among existing prime movers. A key success factor has been the development of integrated engine functionalities that enable low emissions, and high engine efficiency of up to 50 percent in single cycle mode, depending on the engine type.”

Let’s move to European driver

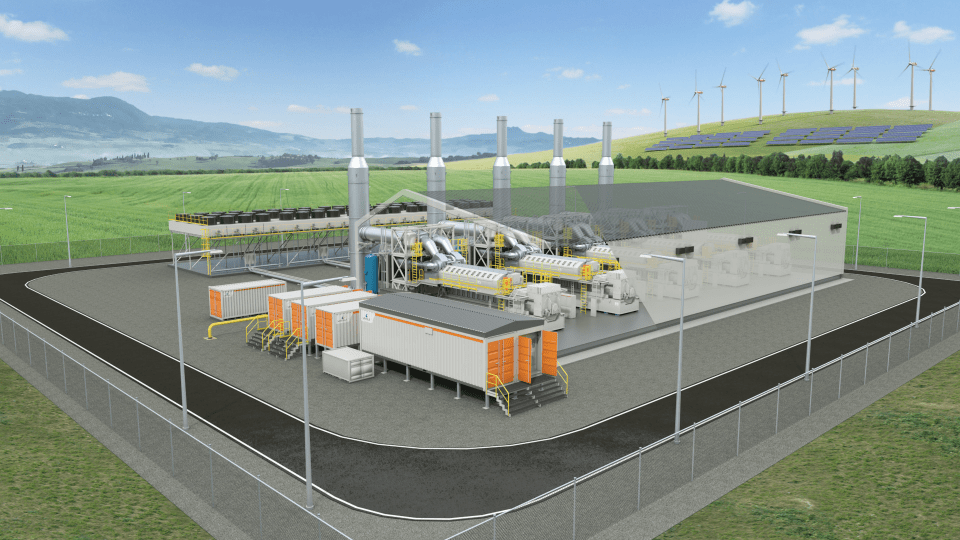

“The CHP plant supplied by technology group Wärtsilä to Kraftwerke Mainz-Wiesbaden (KMW) in Germany has been officially handed over for commencement of commercial operations. The handover took place on 23 December, allowing municipal energy provider KMW to reliably provide 100 MW of electrical power. The CHP plant feeds the excess heat generated during power generation into the Mainz district heating network. From this, Mainz customers are supplied with sufficient heat to supply around 40,000 modern single-family homes.The state-of-the-art plant operates with ten gas-fuelled Wärtsilä 34SG engines. The operational flexibility of the plant enables KMW to start and stop the engines without limitations as fast as in 2,5 minutes. This provides essential grid balancing support as the power system incorporates ever increasing renewable sources, namely wind and solar. It also allows KMW to operate in the short-term balancing markets, since power output can be quickly adjusted to respond to fluctuations in the power demand, as signalled by the electricity price.

As part of its climate action plan, the German government has committed to increasing the share of electricity produced by CHP plants to 25 percent of the total electricity production by 2025. Germany, like the European Union, aims to become greenhouse gas neutral by 2050. It has set the preliminary target of cutting emissions by at least 55 percent by 2030 compared to 1990 levels. Wärtsilä supplied and built the plant on a full engineering, procurement, and construction (EPC) contract. The scope also includes a comprehensive 15-year maintenance agreement that guarantees the plant’s availability and reliability. The services provided include on-site support and remote online monitoring conducted via Wärtsilä’s asset diagnostics and expert analyses. This ensures sufficient capacity at all times, especially during periods of high demand in winter.”