Aumet and Z-engine technology to reduce CO2 and NOx

The Finnish company Aumet has been working on 2-4 stroke diesel Z-engine technology with the aim of reducing NOx and CO2 emissions. Let’s have a look at how they explain such a development. «Hybridization helps ICE car to recuperate the braking energy, even very small batteries, 1-2 kilowatts are big enough for this purpose in […]

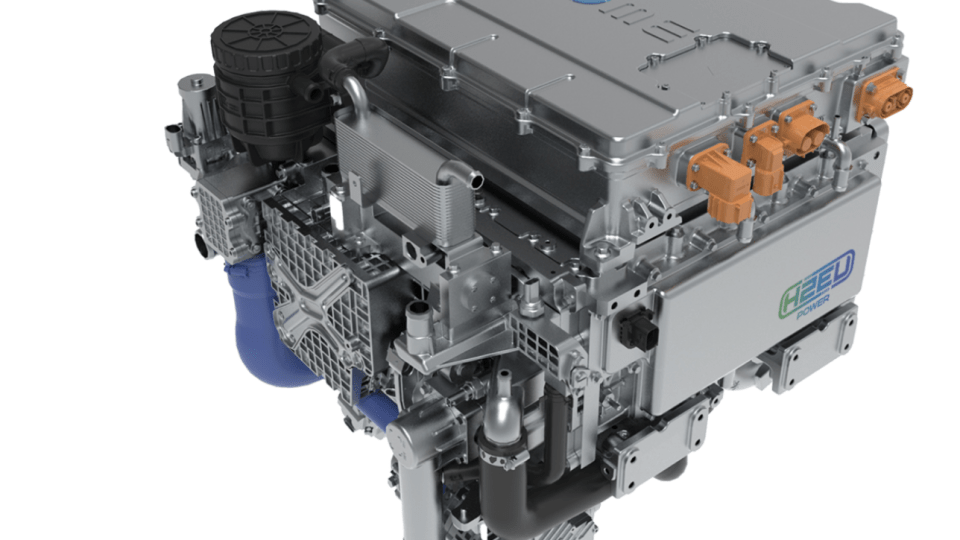

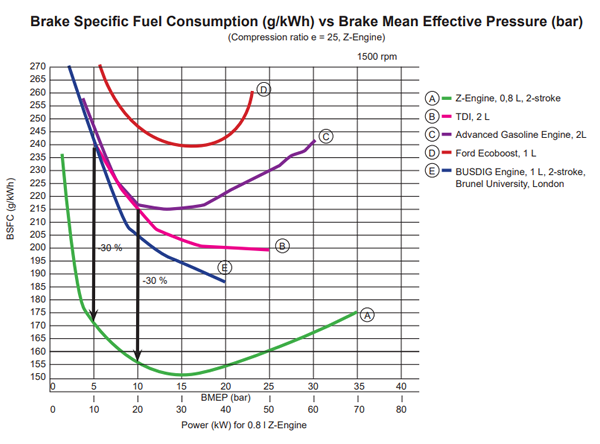

The Finnish company Aumet has been working on 2-4 stroke diesel Z-engine technology with the aim of reducing NOx and CO2 emissions. Let’s have a look at how they explain such a development.

«Hybridization helps ICE car to recuperate the braking energy, even very small batteries, 1-2 kilowatts are big enough for this purpose in passenger cars, but also other actions are needed to solve NOx and CO2 problems. The split-cycle engine, where compression is partially or totally transferred outside the work cylinder, is a new development in combustion engines. This offers new thermos-dynamical possibilities to adjust the working cycle and the combustion. As there are methods to control the temperature at TDC, a HCCI combustion is possible in the Z-engine at all loads».

Aumet’s 2-4 stroke diesel Z-engine and RCCI combustion

«The new trend in car engines is HCCI-combustion, for example Mazda and Honda have published information about their HCCI projects. HCCI has lower heat losses and quicker combustion than normal combustion and therefore better efficiency and also lower emissions. Aumet’s 2-4 stroke diesel Z-engine works with spark controlled single fuel RCCI combustion. When controlling the ignition point with spark, the best efficiency can be achieved and it is possible to avoid too high pressure in the cylinder. The air-fuel mixture in Z-engine is lean, lambda 1,3-1,9, containing about 10 percent IEGR and 25 percent LPEGR. IEGR makes possible the main fuel rapid evaporation during the main fuel injection and it also makes the formation of active radicals possible, thus lowering the activation energy of the fuel. LPEGR contains a lot of water steam and when it condensates in the high-pressure intercooler, the water can be injected to the intake ports of the Z-engine for controlling TDC temperature».

More technical insights

«The controlled turbo bypass channel helps to keep the IEGR pressure in cylinder at the end of exhaust cycle at about 2 bar. Thus, the main fuel injection with outwards opening conical nozzle can form a homogenous mixture in the cylinder. As TDC temperature in Z-engine is low, the main air-fuel mixture in the cylinder is lean and its Livengood-Wu integral can be kept between 0.7-0.8 so self ignition can’t occur. The ignition injection with side injector forms a rich mixture around the high voltage spark electrodes and as this fuel is fully evaporated, it is easy to ignite accurately with high voltage sparks».