Deutz and Stage V. The beauty of innovation

Deutz and Stage V. A story that began with the flourishing of the first ‘Stage V ready’ cards at Intermat in 2015, which found its consecration there with the certification of TCD6.1. The first industrial engine to bear the title of ‘Stage V Compliant’ by the European Union was him, followed by the 3.6 and […]

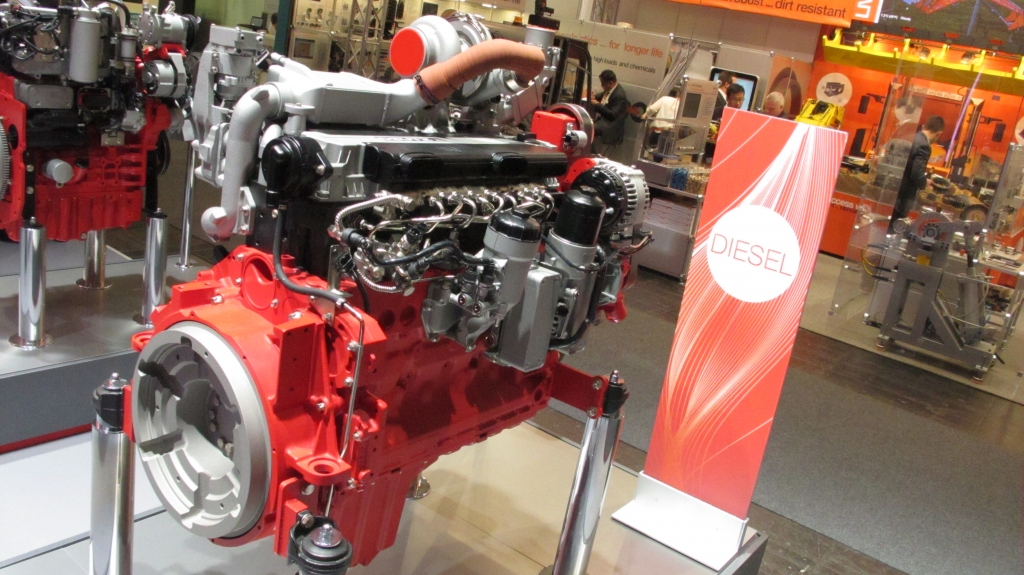

Deutz and Stage V. A story that began with the flourishing of the first ‘Stage V ready’ cards at Intermat in 2015, which found its consecration there with the certification of TCD6.1. The first industrial engine to bear the title of ‘Stage V Compliant’ by the European Union was him, followed by the 3.6 and 7.8 liters displacement engines.

DEUTZ AND STAGE V MEANS IN LINE ENGINES AS WELL

The keystone is the virtuous processing of the regeneration process and Deutz has decided to calibrate the mode of operation according to the workload. The Heat Management system manages the regeneration cycle, the so-called ‘Heat Mode‘ regulates the temperatures, substantially increasing the heat level to ensure proper cleaning of the honeycomb weft of the DPF. And this does not only apply to TCD6.1. Currently the entire range from 2.2 to 16 litre engines is Stage V approved.

The first one was been the TCD6.1

The Stage V certificate was issued on 6 September at TCD 6.1 in Deutz by the German Federal Authority. In November it was the turn of TCD 3.6, 4.1, TCD7.8 and TTCD 7.8.

We asked to Roberto Brivio, Deutz Italy CEO, some details more.

BRIVIO, DEUTZ ITALY AND 30,000 ‘RED’ ENGINES

«As for the 4 to 8 litre Diesel engines series, the technical equipment of the engine does not change in the hardware, except with minimal changes and all internal to the engine, without this interfering in the management activities of the customer» Brivio said.

Deutz and Stage V? Quite a plug-in

«This series also in Stage V is configured as a plug-in. The changes are limited to the software, the certification and homologation procedures, the engine nameplate and the service commissioning. The new element of the European legislators for engine manufacturers concerns the correspondence between the homologation data and the real ones. We move from DOC to a DOC-DPF combination in the range below 56 kilowatts; above, we move from DOC-SCR to DOC/DPF-SCR. The macroscopic advantage of this solution is found in the mixing pipe, the urea mixer, a body existing between DOC and SCR, which disappears to be integrated into the body of the DOC/DPF, centrifugal and no longer linear».

TALKING WITH MICHAEL WELLENZOHN