Ecospray “green” point of view from Viareggio

Ecospray Technologies mission is to make the toxic hemisphere of exhaust gases more “green”. Nitrogen oxides, sulfur oxides, graphite residues. Consolidated skills in the industrial sector that Ecospray intends to bring to nautical applications. We talked about it in Viareggio, at the Versilia Yachting Rendez-Vous, with Pierangelo Ponzoni, Director of industry & renewables, and Fabio […]

Ecospray Technologies mission is to make the toxic hemisphere of exhaust gases more “green”. Nitrogen oxides, sulfur oxides, graphite residues. Consolidated skills in the industrial sector that Ecospray intends to bring to nautical applications. We talked about it in Viareggio, at the Versilia Yachting Rendez-Vous, with Pierangelo Ponzoni, Director of industry & renewables, and Fabio Calcagno, Marine technology manager.

Can you talk about the current projects?

We operate historically in DeNOx on an industrial level and it is our intention to transfer this experience into the naval world, both captive and OEM oriented. Currently (editor’s note, 9 May 2019) we are creating a new division purely oriented to the realization of systems for the reduction of polluting substances such as NOx, Particulate, Methane Slip, in partnership with a leading company operating in the Chinese market, already producing catalytic and filtering substrates for the automotive segment (truck, light duty vehicle, car, motorbike).

The components supporting the system, such as reagent dosing and automation controls, also refer to the same automotive type in order to contain the dimensions to facilitate installation on board. The philosophy that inspires this project proceeds in the direction of uniting our experience in industrial DeNOx with the proper competence in the supports and in the chemistry of the same (the substrates for the chemical/oxidative and/or filtering reaction). We are among the few to offer catalysts and their system engineering, integrating the skills and vertically aggregating the manufacturer and supplier of catalysts with system engineering.

So which kind of services will the Chinese partner provide?

It will deal with the treatment of substrates, so that they produce the desired effect. Their specialization is in systems for engines from 50 to 130 kilowatts for automotive applications. Our aim is to industrialize these systems for the naval industry.

And which are your main targets?

Yacht propulsion at 10 MW and above for commercial applications.

And the retrofit for Tankoa?

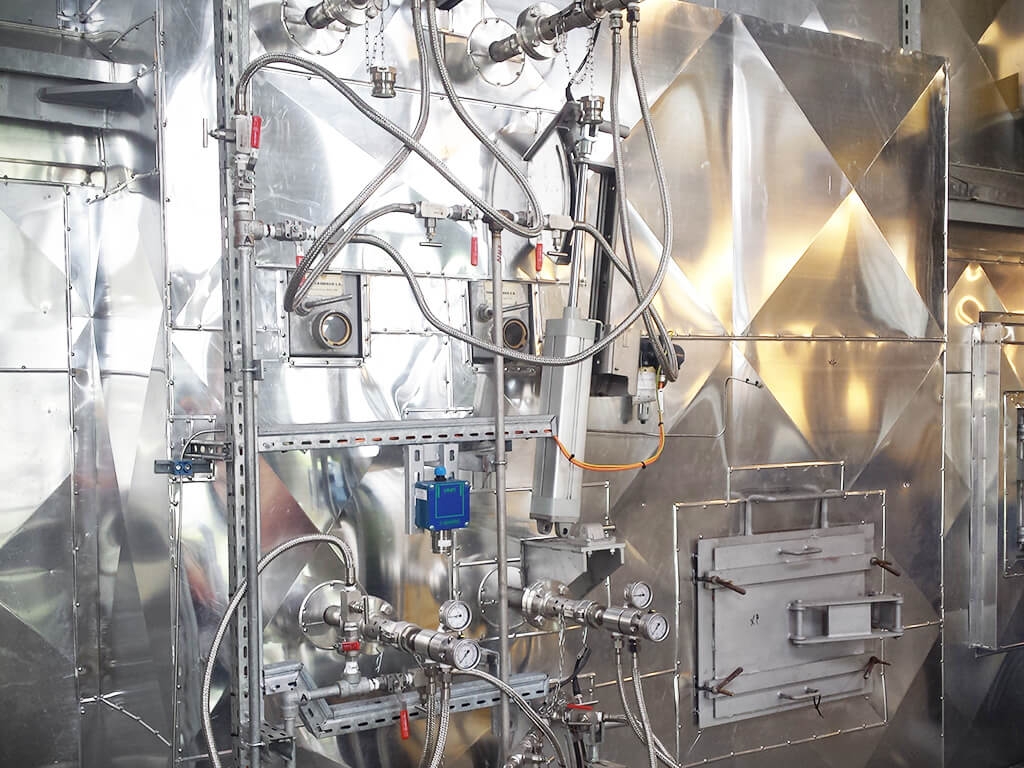

With Tankoa Yachts we followed the development of the DeNOx system for a 72 meter yacht with the upgrade of the engine, originally Tier1 certified, with the problems related to installation in small spaces. The collaboration continued with the analysis of the type of certification required and ended with one of the first Tier3 approvals. On the Tankoa superyacht we have also installed a system that deals with a partial treatment of the fumes, in addition to noise reduction.

So do you believe in the retrofit option for yachts?

This activity will become the core business, as far as NOx reduction is concerned. The part concerning noise pollution is marginal, there is no reference standard, apart from the RCD2, linked to yachts up to 24 meters.

What is the reaction of the shipowners?

These technologies are “environmental driven” and necessarily require very far-sighted owners, such as Tankoa, or the imposition of rules and regulations by the authorities. The Eca areas are currently only related to SOx and only to the USA and Canada for NOx. The legislative driving force can only come from IMO.

What is your target for the commercial sector?

Technically there are no application limits. The problems can come from two-stroke engines, because exhaust temperatures can be too low for a DeNOx system, and from engine room space.

We are also working with scrubbers in the “lake world”, where there is, like in the marine world, the problem of reducing combustion fumes.

How does urea react on these applications?

Urea is a distributed solution with different levels of concentration. In industry it is used at 40-45 percent, in the marine and automotive sectors at 32 percent, with a point of crystallization at -5°C, even lower than water, so the problem of solidification does not arise, unless you sail in particularly cold areas, such as Alaska… There are technical peculiarities to consider in the dosing systems, related to washing and evaporation. When in contact with heat the water evaporates and the solid remains, the salt, which could eventually plug the injection lances, the pump, etc.

And what about electronic engines?

The upgrading clearly favors mechanical engines. With the supercharged common rail, as on the aspirated common rail, there is no limitation. The problems are given by the need to reach the temperatures necessary for catalysis.

The problems are related to the use of the engine and the operation of the boat. I give you the example of heavy fuels: by cooling, they undergo the possible formation of phosphates. Lately on naval applications we push on the metal catalyst a lot, due to the fragility of ceramic supports, sensitive to sound waves of vibrations. As an alternative we propose metallic supports: on the one hand they have a different prices, on the other a longer duration and fewer problems.

Certification tests?

There are two types of certification: type A and type B. They differ in their applicability to the engines and execution methods.

Type A certification, typically the classic test to be performed, tests the engine + bench SCR system, measuring various parameters. The on-board verification procedures are then defined, following which the IAPP certificate is issued.

Type B certification is instead undergone in all those cases where A is not feasible; in which case the engine and SCR are tested separately and then the final test is issued to receive the certificate.

What problems can the DPF bring?

In itself, none. Problems with regeneration could arise. For this reason we are developing thermal or oxidative regeneration systems that do not involve the presence of flames. The R&D department, together with some European partners, is applying on an oxidative box, self-oxidizing filters that produce oxidative gases inside, using special minerals, and with a modest increase in temperature obtain this effect, to avoid post-injections or resistances.

What about LNG and gas in general?

We have developed a technology for biogas upgrading, produced from biodigesters from landfills and agricultural residues. We are building the first plant in a landfill in Northern Italy, of an industrial demonstration type. We also deal with the liquefaction of the Bio-LNG which, tomorrow, we trust will constitute at least a part of the naval engine supply, to reduce the emission of CO2 into the atmosphere. The shipowners have set themselves the goal of reducing emissions by 30 percent by 2030 and by 50 by 2050. The first LNG-powered ship of the Carnival group was launched in December 2018 and sails in the Mediterranean, and 10 more will be added soon.