ETW and CHP: a German case study

ETW and CHP, two acronyms in the name of energy efficiency. The German company has been developing and producing energy plants since 1997, in the output range of 400 to 4,600 kWel. We forward an interesting case study. ETW and CHP: to expand a biogas plant into storage power plant In Wehrbleck in Lower Saxony, the […]

ETW and CHP, two acronyms in the name of energy efficiency. The German company has been developing and producing energy plants since 1997, in the output range of 400 to 4,600 kWel. We forward an interesting case study.

ETW and CHP: to expand a biogas plant into storage power plant

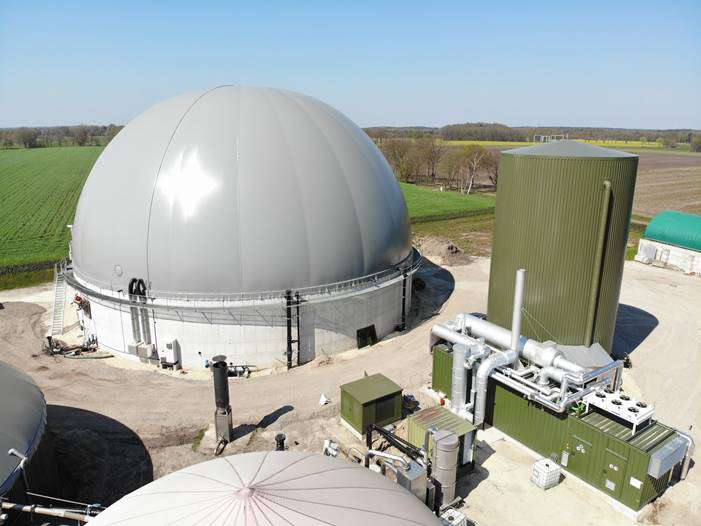

In Wehrbleck in Lower Saxony, the company ETW Energietechnik from Moers expanded an agricultural biogas plant into a regenerative storage power plant in 2019. The CHP experts were supported by the planning company Energethik from Osnabrück. In addition to the new Flex CHP with the TCG 2020 V20 biogas engine from MWM with 2 megawatts, electric and 2.3 megawatts, thermally, ETW also installed a combined gas storage tank with 8,490 and a heat storage tank with 1,000 cubic metres. The total investment amounts to 1.6 million euros.

Since 2001, farmer Andreas Rohlfs has been operating a biogas plant with an area of around 235 hectares. Based on the input materials maize, dung and liquid manure, the operator generated around 5.4 million kilowatt hours of electrical energy and 4.1 million kilowatt hours of thermal energy before the expansion. Since its expansion into a storage power plant, the plant now produces 5.7 million kilowatt hours of electrical energy and almost 5.8 million kilowatt hours of heat per year. The electricity is fed into the grid; the waste heat is fed into a district heating network for heating private and municipal buildings and is used to dry wood chips. Part of the heat is diverted to keep the engine warm when it is not running. This allows the direct marketer to quickly restart the engine if necessary and immediately access the full output of the CHP.

In addition to the increase in output, the plant now operates flexibly. In return, Rohlfs will earn an additional flexibility surcharge of 40 euros per kilowatt over the next five years. Afterwards, the farmer can optionally apply for a further ten-year EEG payment by means of a tender. His main advantage: thanks to the Flex CHP, his plant is now operated in such a way that electricity and heat can always be fed in at the most productive time of day. For this purpose, the biogas plant is controlled by a direct marketer in such a way that the storage tanks are always optimally filled when prices are at their highest and that the largest possible quantities of electricity and heat are available for this purpose.

The plant is powered by desulphurised biogas. For this purpose, the sulphur content is conditioned down from around 5,000 parts per million (ppm) to around 2 ppm. A safety alarm with integrated stop of the gas supply to the storage protects the CHP at a sulphur content above 2 ppm. This is particularly necessary because the sulphur content can rise faster in flex operation. After the preventive shutdown, operation of the engine is maintained with the gas from the storage tank.

«In order to be prepared for future NOx limits, ETW has already reserved the necessary space on the CHP container for an SCR catalytic converter. The plans also take into account a reserve for exhaust back pressure,» explains Alexander Szabo, the responsible sales manager at ETW Energietechnik.

To improve flexibility

The variation of the substrate quantities also contributes to the flexibility of the CHP operation. This makes it possible to reduce biogas production at low electricity prices so that the CHP unit can be shut down for up to two days if necessary without overloading the gas storage tank. The heat storage tank can store 40,600 kilowatt hours of thermal energy and thus supply the heating network for around 50 hours without the CHP unit having to be put into operation. The bottom line is that the CO2 savings achieved by the regenerative storage power plant in electricity production can be estimated at 2,683 tonnes per year and in heat production, including process heat, at around 1,300 tonnes.