A broad range of e-machines. JCB keeps on pushing on electrification

JCB keeps on pushing on electrification for its range of construction and agricultural machines. Also, the global company has recently introduced a couple of very interesting innovations: from the power pack for off-grid applications to the universal charger.

JCB keeps on pushing on electrification for its range of construction and agricultural machines. Also, the global company has recently introduced a couple of very interesting innovations: from the power pack for off-grid applications to the universal charger. The following in an excerpt of the article you may find at page 34 of Diesel International 3/21.

As a matter of fact, JCB has believed in electrification since the year 2018, when the first example of an electric mini-excavator was launched and went into production the following year, also winning awards for innovation in the UK. The vision, we might say, is clear and leads towards a highly modular offer according to the type of machine required, the emission standards in force in a given territory and, above all, the needs of each customer. Not too far away, customers will also be able to choose the propulsion technology for their entire range of construction and agricultural machines, without giving up performances. There’s also something to say about hydrogen.

JCB believes in electrification… and works on recharging

Talking about recharging, JCB has recently introduced two different and complementary options, namely the Universal Charger and the Power Pack. The first one is a universal fast charger, compatible with current and future E-Tech electric models with 48, 96 volts and above. The Power Pack, on the other hand, is a backup solution conceived for urban construction sites and locations that doesn’t have a power grid. Both solutions have been designed and implemented in-house, due to an R&D department that is rapidly gearing up for this type of requirements.

The new JCB electric machines

But let’s get down to the machines, and to a range that is rapidly expanding and now also includes the electric version of the HTD-5 Dumpster tracked carrier equipped with a 9 kW electric motor that allows a maximum travel speed of 3 km per hour, as well as a 48V lithium-ion battery pack that can be recharged in two hours using a 240 or 110V electrical supply. In the dumper segment, the 1TE electric high-loader model with a maximum payload of one tonne is a step up in size, as it incorporates electric powertrain in a basically heavy-duty vehicle, conceived especially for the European and North American markets.

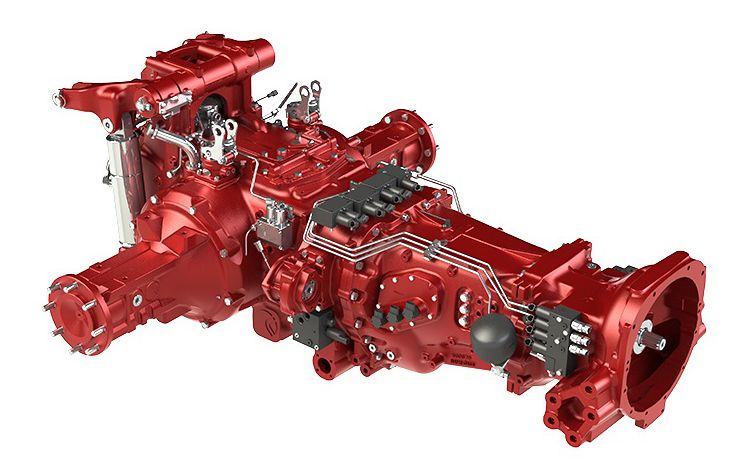

The E-dumper’s partner of choice on site is the aforementioned mini excavator, JCB’s first major zero-emission vehicle. The 19C-1E will now be equipped with a fully glazed cab, making it attractive for countries with very cold and wet climates. Finally, a new ‘electric’ life has also been breathed into one of the iconic machines in the JCB galaxy, the 525-60E telehandler, which uses «two proven electric motors, one for the transmission and the second to manage the hydraulics. The four-wheel drive system uses new high efficiency axles, driven by a large inboard mounted electric motor connected to the driveline via a drop box».