JCB brought hydrogen to Agritechnica 2023

JCB showcased the hydrogen engine and electric telescopic handler Loadall 525-60E at Agritechnica

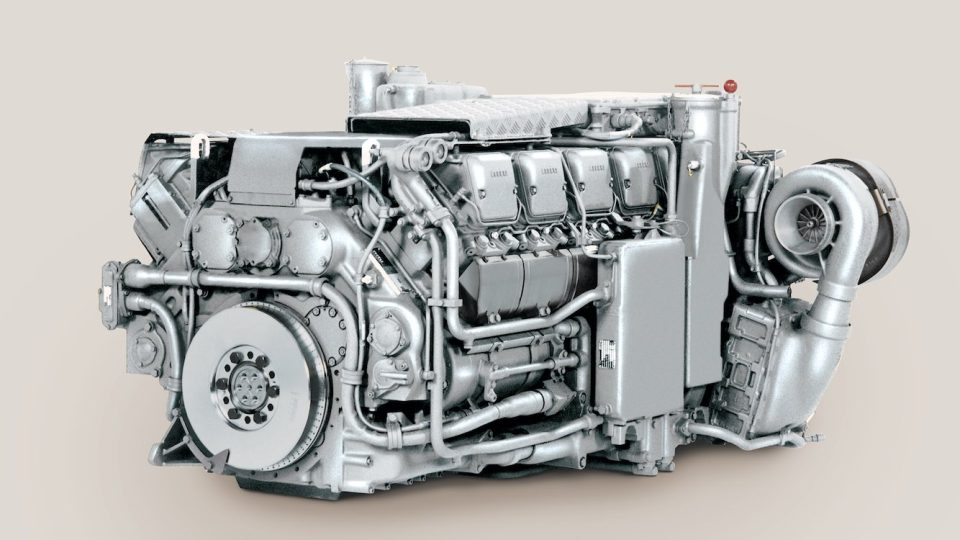

JCB’s connection with hydrogen was confirmed at Agritechnica 2023. After the presentation in the quarry in the UK, which we attended, the Hanover showcase was an official investiture for the agricultural scenario. A team of 150 engineers is working on the pioneering project to develop hydrogen combustion engines, and more than 75 prototypes have already been produced at the JCB engine plant in the UK.

For hydrogen Jcb also at Agritechnica 2023 imagines a tank in the trailer of a Fastrac tractor

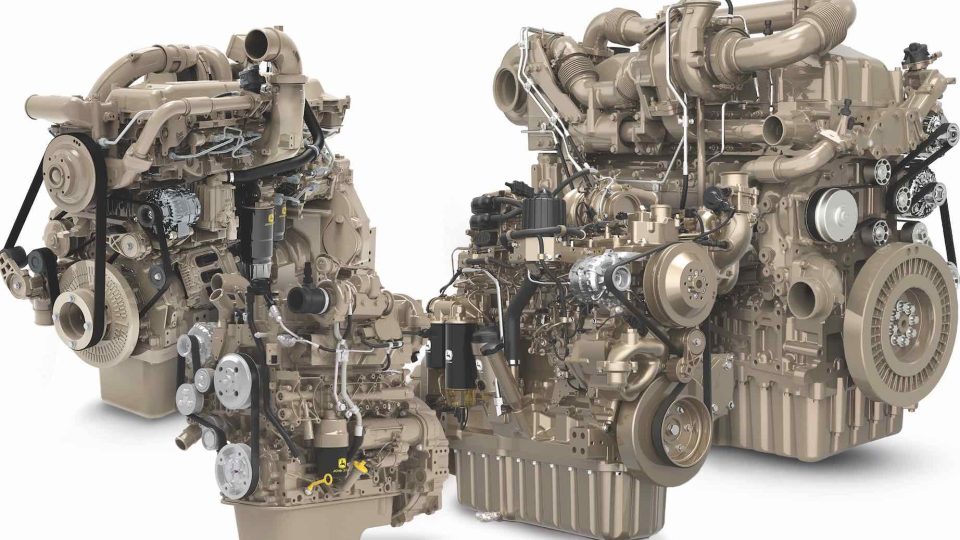

JCB hydrogen engine prototypes are already powering models of telescopic handlers and backhoe loaders. The British company also took a major step forward by demonstrating the wider appeal of hydrogen combustion technology by installing hydrogen engines in a 7.5 tonne Mercedes truck and a Mercedes Sprinter van: retrofits completed within days. JCB also presented its mobile refuelling system designed and built to bring fuel to the cars. The tank has enough hydrogen to fill 16 hydrogen backhoe loaders and can be transported on the back of a modified Fastrac or on a trailer. JCB has also been at the forefront of developing electric technology to meet customer demand for zero-carbon products. While battery-powered electricity is suitable for smaller machines that do fewer hours and generally use less fuel, larger machines have higher energy requirements. This would result in larger batteries taking longer to charge, making them less suitable for machines that work multiple daily shifts and have no downtime available to recharge.

There is also room for electrification

JCB has focused the development of electric machines on its compact range, including the 403E compact wheel loader, the Loadall 525-60E telehandler and the 19C-1E mini excavator. As the company examines future zero-emission fuels, it has left no stone unturned. In its search for a mobile fuel that can be brought to the machine, ensuring maximum uptime and quick refuelling, HVO, biogas, electronic fuels, ammonia and hydrogen were all examined under the microscope. Jcb engines have been approved for use with HVO since the Stage IIIB/Tier 4i engine legislation came into force.

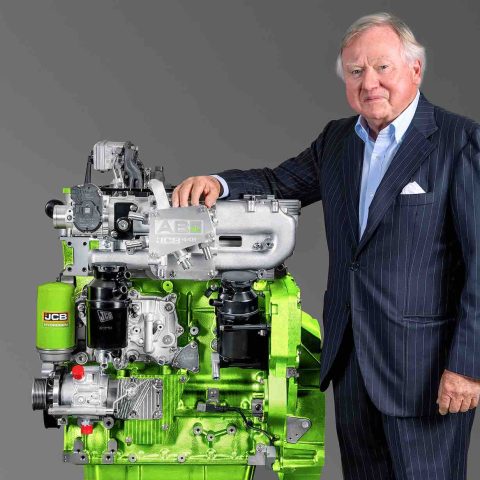

Lord Bamford said: “Most of these alternative fuels require hydrogen to produce them, so it makes perfect sense to use hydrogen in the first instance because it is a clean, zero-carbon fuel that can be produced from renewable energy. Hydrogen also offers a potential solution to the challenge posed by batteries on larger cars; it allows for quick refuelling and is a mobile fuel solution, allowing fuel to be brought to the car”.

And what about fuel cells?

As part of its hydrogen development, JCB has also studied its use in fuel cells and in July 2020 unveiled the construction industry’s first hydrogen-powered excavator: a 20-tonne 220X. For the time being, Jcb has come to the conclusion that fuel cells are too expensive, too complicated and not robust enough for construction and agricultural equipment. Challenging the JCB engineering team to think differently and using the technology around us in a carbon-neutral way, the JCB hydrogen engine was born.

Lord Bamford stated: “The unique combustion properties of hydrogen allow the hydrogen engine to provide the same power, torque and efficiency that powers Jcb machines today, but with zero carbon emissions. Hydrogen combustion engines also offer other significant advantages. Using diesel engine technology and components, they do not require rare earth elements and, crucially, the combustion technology is already well proven on construction and agricultural equipment. This technology is cost-effective, robust, reliable and well known not only in the construction and agricultural sector, but worldwide.”