NGV Powertrain. Mission: ‘gas’

Here’s the mission of NGV Powertrain: becoming the partner of choice of small and medium vehicle manufacturers wishing to convert their diesel engines to gas – worldwide. We’re still in the ICE galaxy then, all applications, none ruled out. 4e-consulting is the partner. Methane gas, and even more so biomethane, also represent viable strategies for […]

Here’s the mission of NGV Powertrain: becoming the partner of choice of small and medium vehicle manufacturers wishing to convert their diesel engines to gas – worldwide. We’re still in the ICE galaxy then, all applications, none ruled out. 4e-consulting is the partner.

Methane gas, and even more so biomethane, also represent viable strategies for emancipation from the ‘vagaries’ of thermal engines. NGV Powertrain wants to become the world’s leading technology partner for small and medium-sized OEMs who want to repower their drivelines. We asked David Caponi, one of the two partners.

NGV Powertrain, the early days.

Let’s leap back in time. NGV is firmly rooted in Reggio Emilia, Italy. Back in the 90s it was split into two separate entities: NGV Bus – dealer of MAN, Solaris, Van Hool and a few DAF applications – and NGV Gas; this latter drew on previous experiences from the 70s and dealt mainly with repowering.

As one may easily infer from the name, repowering with NG.

Precisely. The company transformed circulating diesel-powered vehicles – buses and trucks – into vehicles running on alternative fuel such as methane. Being a worldwide player, NGV Gas was attractive first and foremost price-wise; secondarily, also in terms of exhaust gas reduction. Huge credit for this mission goes to my partner Luca Iori – who created it alongside his father.

As that was, by all means, an innovative way of working.

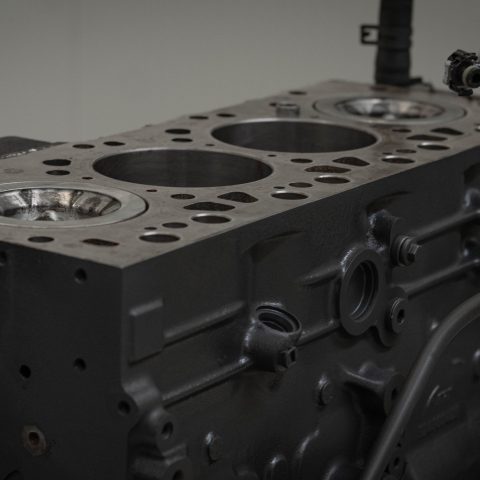

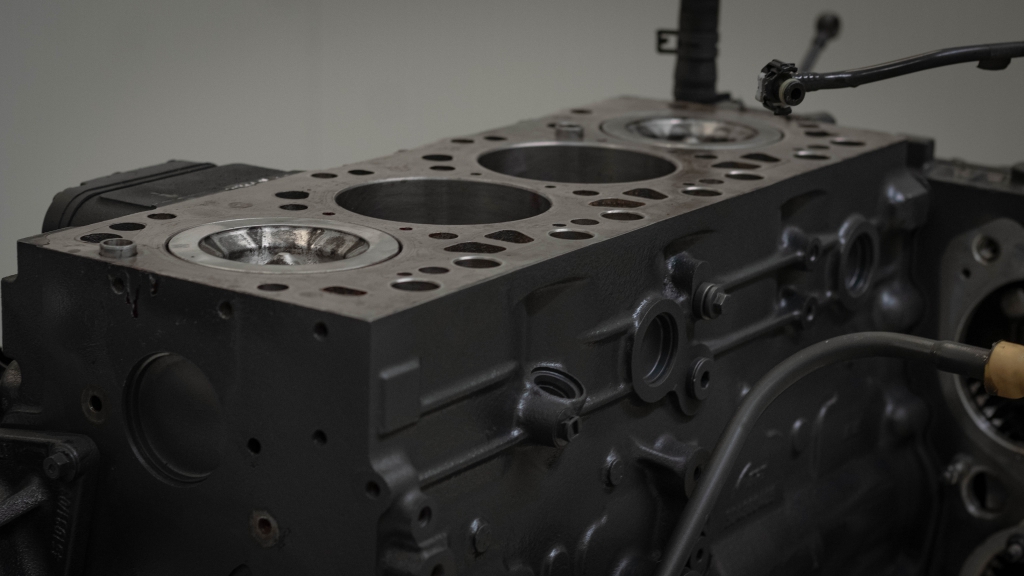

Not a speck of doubt about that. At the Reggio Emilia plant they used to set up a prototype demonstrator based on a customer-sent diesel engine that was dismantled and altered to run on natural gas in the workshop. Secondly, they added the relevant manuals and technical datasheets in the customer’s native language. Once the preliminary development stages were done with, NGV Gas staff was sent at the customer’s site to teach its workers how to operate the transformation. To name an example, some 20,000 Ashok Leyland buses were converted this way at Indian plants.

Like some kind of flying doctors?

We could call them flying teachers. Customers were very satisfied with the fact they were actually importing know-how and producing locally. As for NGV Gas, that’s how it managed to stay small-sized: all it had to do was sending small teams of people mastering that know-how around the world; there was no need to set up its own manufacturing lines requiring the huge investments that are typical of our sector.

READ THE ARTICLE, PUBLISHED ON DIESEL INTERNATIONAL MARCH 2021