Schaeffler in Munich and Hannover between electric motors and electrolyser

Schaaeffler showed its more alternative side, at bauma with electric motors, at Hannover Messe with the electrolyser

Schaeffler presented itself at the trade fairs in Munich and Hanover with what it needs for today and tomorrow. What do that mean? That there is something for everyone, including rolling bearings and low-friction sensors. The hot topics, however, are those written in capital letters on the decarbonisation agenda.

What’s the buzz in Munich? Let’s talk electric motors

The Schaeffler portfolio in Munich, and everywhere else, regarding electric motors covers all common voltage ranges up to 800 V, for a maximum continuous output of 300 kW. Please note, although the road footprint of the German group’s technology naturally links up with the off-highway, in this case we are talking about applications specifically designed for construction machinery.

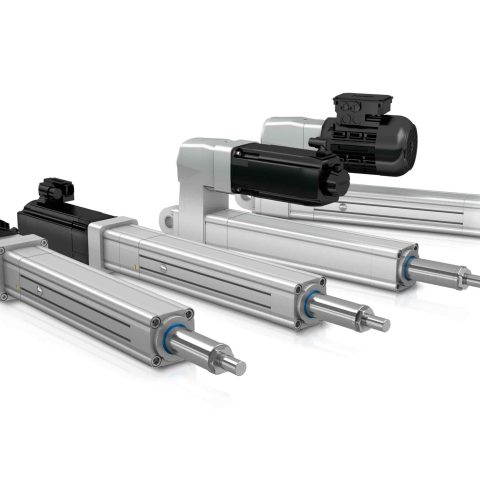

A key point on the Schaeffler booth are the electric motors with a maximum speed of 10,500 rpm and a continuous output of 219 kW. The oil-cooled motors claim an efficiency rate of over 97%. The modular electromechanical linear actuators are suitable for both operational functions and the automated operation of flaps and engine bonnets. The series covers nominal forces from 1.5 to 150 kN and stroke ranges from 300 to 2,000 mm and is designed for small excavators, wheel loaders and mobile work platforms, among other applications.

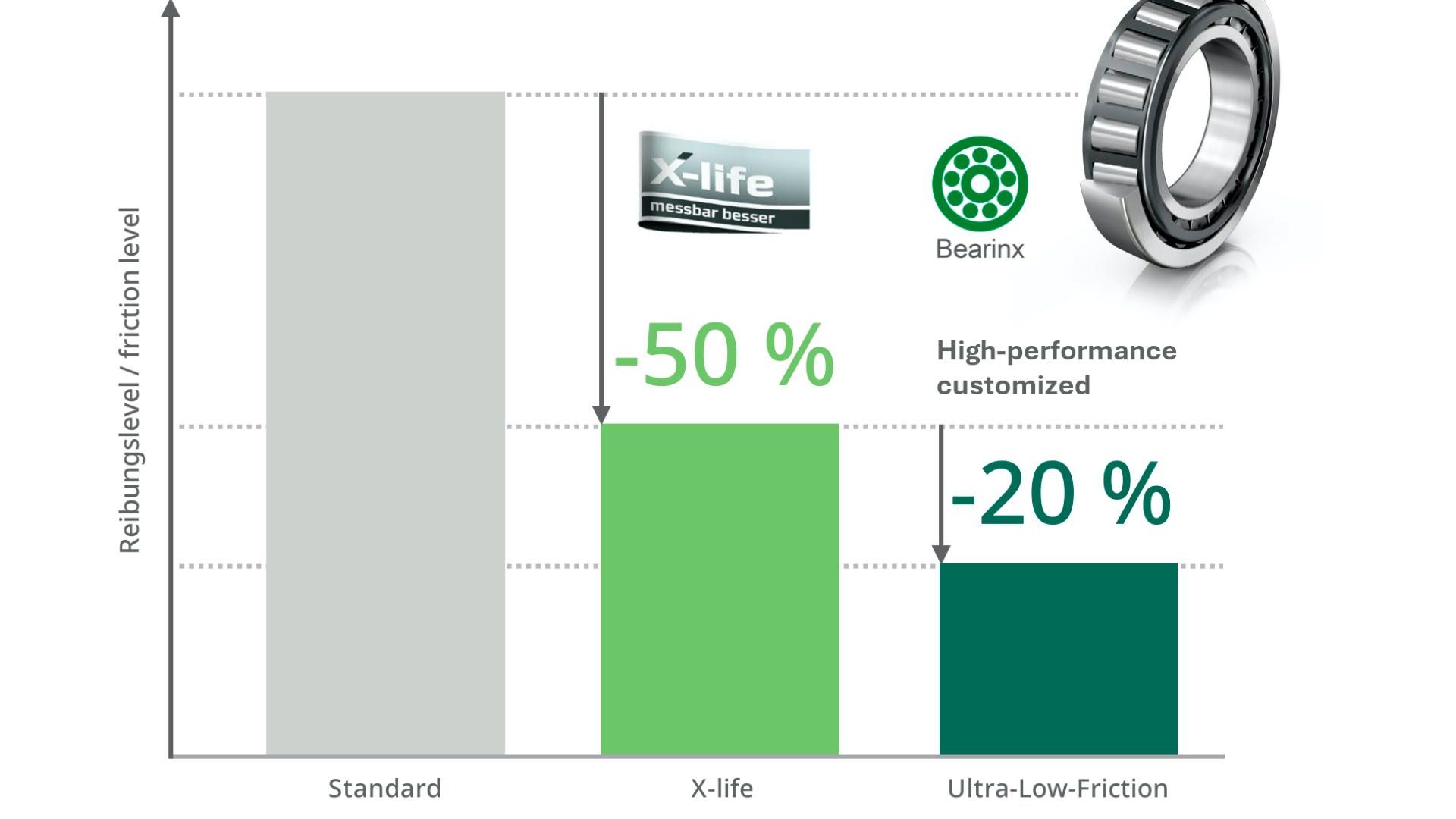

We mentioned Schaeffler’s low-friction rolling bearings at the beginning, which include a tapered roller bearing line with optimised flange contact and a further improved raceway surface structure, compared to the previous generation. According to Schaeffler engineers, they enable significant savings in hydraulic motors and pumps in applications such as wheel loaders, and beyond. On 1,000 construction machines, they estimated annual savings potential of around 26,000 MWh with 8 hours of operation.

And green hydrogen? Not a pipe dream for Schaeffler

Let’s stay in Germany and move north. It is not time for Agritechnica, but for the Hannover Messe, where Schaeffler presented an electrolyser with powers of up to 1 megawatt, as well as fuel cell stacks and bipolar plates with the innovative Enertect coating. According to Florian Windisch, Head of the Hydrogen Business Unit, “Schaeffler’s goal is to drive the energy transition and thus the decarbonization of various industrial sectors. To achieve this, industrial-scale production of green hydrogen is crucial. At Schaeffler, we focus on the entire hydrogen value chain – from production via electrolysis to the use of hydrogen in fuel cells.” The electrolyser is capable of producing around 450 kilograms of hydrogen per day. Schaeffler’s product range includes stacks of proton exchange membrane electrolysers (PEM) with scalable capacities from 50 kW to 1 MW. Smaller electrolysers are also available without membranes. Also in the case of stacks, the key to usability is power density. Schaeffler’s fuel cell stack, weighing less than 0.5 kg/kW, is equipped with a customised bipolar plate coating system. Enertect coatings are free of precious metals and can be used in both electrolysers and fuel cell systems. The coating reduces the CO2 footprint of the bipolar plate by more than 75% and significantly increases the efficiency of both fuel cells and electrolysers.