ZQuip electrifies the construction site’s fleet

ZQuip kit turns diesel-powered construction fleets into zero-emissions machines

For those who find it too expensive to purchase electric excavators and wheel loaders, ZQuip helps transform machines powered by internal combustion engines into electric machines.

From US to the building yards of all over the world

The conversion kit to turn diesel-powered construction fleets into zero-emissions machines comes from the United States. “The 700V ZQuip Energy Modules are at the core of this innovation. ZQuip modules are interchangeable across any machine we convert regardless of size, type, or manufacturer, and will enable a level of serviceability, run-time, and value that is far greater than current battery solutions,” said Chris LaFleur, managing director for ZQuip.

ZQuip in details. The first step has been with Caterpillar

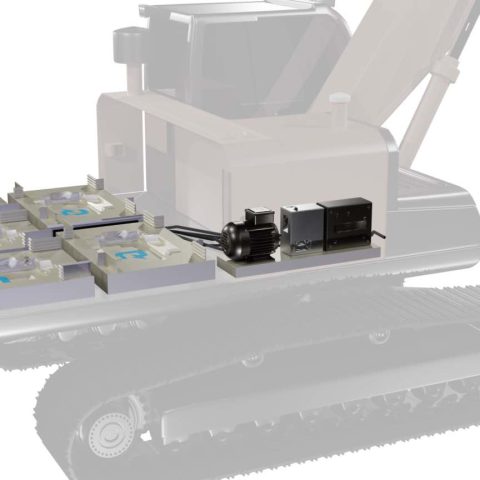

ZQuip first demonstrated this concept with a CAT 308, creating a ZQuip battery-electric version of the classic diesel-powered 8-ton excavator, making it one of the most powerful, energy-efficient and zero-emissions 8-ton excavators available today. The conversion kit includes a battery harness, electric motor, and advanced AI thermal management system. Energy Modules of 70 kWh and 140 kWh are easily interchangeable among all machines. Talking about software, IoT and connectivity features for monitoring fleet activities and battery life, eliminating range anxiety and ensuring maximum uptime.

Chris LaFleur beliefs

“We are not selling individual excavators, loaders, or other machines,” emphasized LaFleur. “The innovation with ZQuip is this: To enable customers to have a zero-emissions work site, we are creating fleets of zero-emissions machines that make the most sense from the perspective of productivity and cost.” According to the company, part of Moog construction, this approach gives customers zero-emissions machines with the exact battery capacity for the job to be done. Imagine a construction site with six ZQuip machines; two need 800 kWh of battery capacity while four require 400 kWh each.

The total energy for the day equals 3.2 mWh. In contrast, today’s traditional all-electric vehicles might come equipped with an 800-kWh battery on each of the six machines mentioned above; in this scenario, the owner would pay 50 percent more for battery capacity that would go unused. With ZQuip, once project managers determine the work to be done, they match the fleet’s energy needs with battery capacity. They then optimize each machine by installing the appropriate number of Energy Modules and, if necessary, swap them across any machine on the job site. Onboard AI Thermal Management technology alerts project managers well before the point when actual energy outstrips what is planned. This ensures project managers have additional ZQuip Energy Modules on site and ready to swap out.